Prepare for an exploration beyond the ordinary cannabis landscape, into a realm where potency, texture, and multi-layered complexity converge. We’re talking about Exotic THCA Moonrocks, those dense, intriguing nuggets that look like they’ve been gathered from some celestial shore. These aren’t merely flower buds; they are meticulously crafted composites, each starting with a core of premium cannabis flower, enveloped in a potent layer of sticky cannabis concentrate, and finally encrusted in a generous coating of pure, shimmering kief. This trifecta of cannabis components results in a product renowned for its intense effects and unique handling characteristics. And so, fasten your seatbelts as we detail the intricate process of how Exotic THCA Moonrocks are brought into existence, from the initial seed right through to their final packaging.

To Buy Exotic THCA Moonrocks Click Here

A Quick Insight into What Moonrocks are

Let’s dive right into it: the composite creation is meticulously assembled in three distinct layers to achieve exceptionally high concentrations of tetrahydrocannabinolic acid. The process typically begins with a solid nugget of cannabis flower, often a quality bud of high-THCA hemp flower to ensure legal compliance (≤ 0.3% Delta-9 THC by dry weight before use). This flower core provides the foundational structure and contributes its own cannabinoid and terpene profile to the mix. Remember, THCA converts to psychoactive THC upon heating, unlocking the potential for profound effects.

The second layer involves coating this central flower bud entirely in a sticky cannabis concentrate. This binding layer is commonly a high-THCA distillate or oil, chosen both for its adhesive properties and its own significant cannabinoid content, further boosting the product’s overall potency potential. This sticky coating acts like a glue, preparing the bud for the final, crucial step in the Moonrock creation process, ensuring the last layer adheres properly and generously across the entire surface.

The third and final layer gives THCA Moonrocks their characteristic appearance and a final, powerful surge of potency. The oil-coated bud is thoroughly rolled in kief – the collected resin glands, or trichomes, sifted from cannabis flower. Kief is naturally rich in cannabinoids (especially THCA in this context) and terpenes. This outer dusting of potent, powdery kief adheres to the sticky concentrate layer, completely encasing the flower bud in a fuzzy, often greenish-golden or brownish coat, resembling a small, textured celestial body – hence the name “Moonrock”.

Therefore, THCA Moonrocks are a potent trifecta: high-THCA flower at the core, coated in high-THCA concentrate/oil, and finally enveloped in high-THCA kief. Every layer contributes to an overall THCA level far exceeding what any single component could achieve alone. This intricate construction results in a product renowned for delivering extremely powerful effects.

What is Initially Needed to Make Exotic THCA Moonrocks?

The successful creation of genuine, high-quality Exotic THCA Moonrocks is fundamentally reliant on sourcing or producing three distinct, premium-grade cannabis components, alongside the specialized tools, environment, and expertise needed to combine them effectively. It’s a vertically integrated challenge demanding excellence at each stage – cultivating stellar flower, producing clean and potent concentrate, isolating pure kief, and skillfully assembling the final product. Compromise on any single element inevitably detracts from the quality and legitimacy of the Moonrock.

For Component 1: The Premium Exotic THCA Flower Core – The Foundation

Elite, Structurally Sound Genetics: The very heart of the Moonrock must be exceptional. This requires indoor-grown cannabis flower selected not just for potency but specifically for physical characteristics suitable for this application:

High Native THCA Content: Starting with flower that is already potent provides a robust cannabinoid base before enhancement.

Rich & Complementary Terpene Profile: The flower dictates the foundational aroma and flavor. The chosen strain should have a profile that will harmonize well with the terpenes potentially present in the concentrate and kief layers.

Exceptional Bud Density and Structure: This is absolutely critical. The buds must be incredibly dense and tightly formed to withstand the handling, coating, and rolling process without disintegrating. Strains known for producing rock-hard, compact nugs are highly preferred over those with looser, more airy structures. Shape also matters; moderately sized, somewhat rounded buds often work best.

Proven Indoor Performance: Genetics must be stable and perform well under controlled indoor conditions to ensure consistent flower quality.

State-of-the-Art Indoor Cultivation Facility: Producing THCA flower of this caliber requires optimal conditions only achievable indoors:

Immaculate Environment: Sealed rooms with non-porous, easily sterilizable surfaces are crucial for preventing contamination that could compromise the flower destined for such a premium application. Air filtration (HEPA) is standard.

Precision Climate Control: Advanced HVAC-D systems capable of maintaining specific temperature, humidity, and VPD targets tailored to maximize density and resin production during the flowering stage.

High-Intensity Lighting: Optimized horticultural lighting (often high-PPFD LEDs) to drive photosynthesis and cannabinoid synthesis, ensuring dense bud development deep into the canopy.

Optimized Growing Systems: Whether hydroponics, aeroponics, soilless mixes (like coco coir), or indoor living soil beds, the system must be managed expertly to produce dense, nutrient-rich, flawless flowers.

Purified Water (RO): Reverse Osmosis water ensures complete control over nutrient delivery, free from unwanted variables in tap water.

Expert Cultivation Team: Highly experienced growers are needed who understand how to push genetics to produce exceptionally dense, resinous buds, and who meticulously manage the drying and curing phases – improperly dried or cured flower will not make a good Moonrock core. Curing must achieve ideal moisture content for structural integrity.

Recommended products

For Component 2: The High-THCA Concentrate Binder – The Potent Glue

Quality Cannabis Starting Material: Whether trim, small buds (“smalls”), or whole flower, the biomass used for extraction should be clean, potent in THCA, and free from contaminants, as extraction concentrates everything present.

Professional Extraction Equipment & Methods: Selecting the right extraction method influences the final concentrate’s characteristics:

Hydrocarbon Extraction (BHO/PHO): Often preferred for creating terpene-rich extracts (“sauce,” “batter,” “sugar”) that offer both potency and flavor, along with suitable viscosity. Requires certified closed-loop systems, explosion-proof environments, and expert handling due to flammability.

Ethanol Extraction: Can produce high-potency oils, but preserving delicate terpenes requires very cold temperatures (cryo-ethanol). Extensive solvent recovery is needed.

Supercritical CO2 Extraction: Creates very clean oil, but often requires post-processing (like winterization) and terpene re-infusion to achieve desired flavor and consistency. High equipment cost.

Solventless Rosin Pressing: Pressing high-quality bubble hash or flower between heated plates yields a solvent-free hash rosin. This is highly desirable for premium Moonrocks due to its purity and rich terpene profile, but requires top-tier starting material (hash or flower) and expertise in pressing techniques to achieve optimal yield and consistency.

Post-Processing & Refinement Capabilities: Transforming crude extract into the ideal Moonrock binder:

Winterization/Dewaxing: Essential for removing fats and waxes, especially from CO2 or warmer ethanol extracts, improving stability and smokability.

Solvent Purging: Absolutely critical for hydrocarbon or ethanol extracts. Requires vacuum ovens capable of maintaining specific temperatures and deep vacuum levels for extended periods (often 24-72+ hours) to remove residual solvents below strict safety limits (<500 ppm or lower, depending on regulations and solvent).

Consistency Adjustment: Achieving the perfect “stickiness” might involve techniques like controlled whipping of hydrocarbon extracts to create batters, or gentle warming of viscous distillates or rosins just prior to application. The concentrate must remain low in Delta-9 THC, meaning decarboxylation must be avoided or strictly minimized during processing. Using pure THCA distillate (carefully produced) or potentially melted THCA isolate blended with cannabis-derived terpenes are other advanced options.

Skilled Extraction & Post-Processing Specialists: Technicians with chemical knowledge, meticulous attention to detail, understanding of thermodynamics, and adherence to safety protocols are indispensable for producing safe, effective, and consistent concentrate binders.

Rigorous Concentrate Lab Testing: Testing verifies high THCA potency, confirms low (<0.3%) Delta-9 THC levels, quantifies terpene content (if applicable), and crucially, guarantees residual solvents are below safety action levels. Pesticide and heavy metal testing on the concentrate itself is also vital.

For Component 3: The High-Quality Kief/Pollen Coat – The Frosting

Premium Cannabis Biomass Source: The quality of the kief directly impacts the final potency boost and flavor enhancement. It should be derived from high-THCA, terpene-rich cannabis material, often the trim and smaller buds from the same strains used for the core flower. Using low-quality starting material results in inferior kief.

Efficient Kief Separation Equipment: Tools designed to effectively isolate trichome heads:

Dry Sifting Equipment: This ranges from simple flat screens of specific micron sizes (e.g., 70-150 microns often capture desirable heads) agitated manually, to multi-screen vibrating sifters, or large rotary tumblers lined with screens. The goal is to gently knock trichome heads loose while minimizing green plant particle contamination.

Ice Water Extraction (IWE) Equipment: Involves specialized mesh filtration bags (bubble bags) of decreasing micron sizes (e.g., 220µm work bag down to 160µm, 73µm, 45µm, 25µm collection bags), ice water, agitation vessels, and crucially, proper drying methods post-collection.

Refinement, Drying & Sieving: Collected kief, especially from IWE, must be thoroughly dried to prevent mold. Freeze dryers are considered the gold standard for preserving quality and creating a fine, sandy texture from bubble hash. Dry sift kief also benefits from further sieving to refine purity. The final kief should be a clean, potent powder, golden or light tan in color, not overly green.

Experienced Kief/Hash Processors: Individuals skilled in operating sifting or washing equipment, understanding micron sizes, and properly drying and handling the delicate trichomes to maximize quality.

Kief Laboratory Testing: Testing confirms high THCA potency, low Delta-9 THC compliance, and screens for any potential microbial contamination or pesticides carried over from the source material.

For the Moonrock Assembly Process:

Documented Assembly Protocol (SOP): A clear, step-by-step guide ensuring consistency in how buds are selected, concentrate is applied (amount, technique), and kief is coated (coverage, handling).

Controlled & Sanitary Workspace: Assembly requires a clean, temperature-controlled area to prevent contamination and manage the stickiness of the concentrate and powdery nature of kief. Good ventilation might be needed depending on concentrate terpenes.

Appropriate Handling Tools: Non-stick gloves are essential. Tools like dabbers, spatulas, or small brushes might be used for precise concentrate application. Trays are needed for holding kief during rolling. Racks or parchment-lined trays are needed for setting the finished Moonrocks.

Recommended products

Understanding the Entire Moonrocks Process

The creation of an Exotic THCA Moonrock is a fascinating multi-stage symphony of cannabis craftsmanship, requiring careful orchestration across cultivation, extraction, purification, and assembly. It’s about taking three distinct cannabis derivatives, each produced to the highest standard, and layering them together in a precise sequence to create a final product that delivers a unique texture and exceptionally high potency.

Here’s a comprehensive walkthrough of the typical production pipeline:

Cultivating the Premium Flower Core: As detailed previously, this foundational step involves the entire lifecycle of growing exceptional indoor exotic cannabis flower. This includes meticulous genetic selection focusing on density and structure, expert management through vegetative and flowering cycles under optimized indoor conditions (light, climate, nutrients), harvesting precisely at peak maturity, careful and aesthetic hand-trimming, a slow and controlled drying period (often 10-14+ days), and finally, a patient and thorough curing process lasting several weeks to months to ensure optimal stability, terpene expression, and the ideal moisture content needed for the subsequent coating steps. Only the best, densest, fully cured nugs are selected.

Producing the High-THCA Concentrate Binder: In parallel, the crucial adhesive layer is developed. This involves extracting cannabinoids and terpenes from chosen cannabis biomass. Depending on the desired end product (e.g., terpene-rich vs. ultra-potent), methods like BHO, PHO, CO2, Ethanol, or Solventless Rosin pressing are employed. The resulting crude extract then undergoes necessary refinement – potentially winterization, definitely solvent purging if applicable (using vacuum ovens to draw out residual solvents to safe levels), and careful processing to achieve a target viscosity. This might involve creating specific consistencies like “live resin sauce,” “batter,” carefully warming high-purity distillate, pressing high-quality hash rosin, or even formulating a binder from melted THCA isolate and cannabis-derived terpenes. The key criteria are high THCA content, low Delta-9 THC (<0.3%), verified safety (especially regarding residual solvents), and a sticky consistency suitable for coating flower evenly.

Collecting & Refining High-Quality Kief: The third essential ingredient, the outer coating, is prepared. This involves mechanically separating the cannabinoid-rich trichome heads from cannabis plant material (often premium trim or small buds). Dry sifting methods use fine mesh screens (common sizes for quality collection range from 70 to 150 microns) and agitation (manual or mechanical tumblers) to isolate the kief. Ice Water Extraction (IWE) uses ice water agitation and filtration through successive micron bags to collect different grades of bubble hash. For Moonrock use, the collected kief or bubble hash must be impeccably dried (freeze-drying is optimal for preserving terpenes and creating a fine texture from hash) and potentially further sieved to ensure a fine, consistent powder free from excess plant particles.

Comprehensive Quality Control on All Components: Before assembly begins, each of the three components must pass rigorous third-party laboratory testing. This critical step verifies:

Flower: Potency (THCA, Delta-9), terpene profile, absence of pesticides, heavy metals, microbials.

Concentrate: Potency (high THCA, low Delta-9), terpene profile (if relevant), absence of pesticides/heavy metals, and crucially, residual solvents below legal safety limits.

Kief: Potency (high THCA, low Delta-9), cleanliness (absence of contaminants).

Preparing Components for Assembly: This involves careful selection and preparation just prior to construction. Only structurally sound, well-shaped, fully cured flower buds are chosen. The concentrate binder is brought to the optimal temperature and viscosity for application (may require gentle warming). The high-quality kief is laid out in a clean tray, ensuring it’s dry and loose.

The Moonrock Assembly – The Grand Unification: This delicate, often hands-on process requires skill and precision:

Step 6a: Applying the Concentrate Layer: Using appropriate tools (like a dabber or small spatula) and wearing gloves, a selected flower bud is carefully and evenly coated with a thin layer of the prepared high-THCA concentrate. The goal is complete coverage without applying an excessively thick or drippy layer, which could make the Moonrock unstable or difficult to handle. Rotation and careful manipulation ensure uniformity.

Step 6b: Applying the Kief Outer Shell: Immediately after the concentrate is applied, while the surface is still tacky, the coated bud is gently introduced into the tray of kief. It is carefully rolled and potentially lightly pressed into the kief, ensuring the entire sticky surface picks up a thick, uniform outer layer of the trichome powder. Complete, generous coverage is the goal.

Setting and Stabilization: The freshly assembled Moonrocks are typically placed on a non-stick surface (like parchment paper on a drying rack) in a cool, climate-controlled environment for a brief period (ranging from a few hours to perhaps 24 hours). This allows the concentrate layer to set slightly, helping the kief adhere more permanently and making the finished product slightly less messy to handle and package.

Final Quality Inspection and Curation: Each individual Moonrock undergoes a final visual inspection. Quality control checks for adequate kief coverage, structural integrity (no crumbling), consistency in appearance, absence of bare spots or excessive stickiness, and overall aesthetic appeal. Any Moonrocks that are misshapen, poorly coated, or damaged are removed from the batch.

Gentle and Protective Packaging: The finished Exotic THCA Moonrocks, now dense and potentially still slightly tacky, must be packaged with extreme care into containers designed to prevent crushing, sticking, and loss of the kief layer, while also preserving freshness.

Recommended products

Why is Each Step Vital to the Moonrocks Making Process Anyways?

The allure of an Exotic THCA Moonrock lies in its potent, multi-layered promise, a promise built upon the successful execution and integration of three distinct cannabis production disciplines. Each step in this complex process is not merely sequential but foundational; a flaw introduced at any stage reverberates through the final product, diminishing its quality, safety, or appeal. Understanding why each phase below is critical, underscores the craftsmanship required to produce genuine, high-end Moonrocks:

Premium Flower Quality & Structure: This is the bedrock. The core flower nug provides the physical scaffolding for the entire Moonrock. If the flower isn’t dense and well-cured, it will compress or fall apart during the coating process. Furthermore, the flower contributes significantly to the overall terpene profile, influencing the taste and aroma that peek through the concentrate and kief layers. Using subpar flower results in a Moonrock that lacks character and structural integrity, no matter how good the other components are.

High-THCA Concentrate Quality, Safety & Consistency: This layer serves two critical functions: providing a major boost in THCA potency and acting as the adhesive for the kief. The concentrate must be potent in THCA while remaining Delta-9 THC compliant. Its safety is paramount – thorough purging of residual solvents (if used) is non-negotiable for consumer health. The consistency (viscosity) is also vital; too liquid and it creates a mess, too solid and it won’t coat evenly or bind the kief effectively. An impure or unsafe concentrate renders the entire THCA Moonrocks unacceptable.

High-Quality Kief Purity, Potency & Dryness: The kief adds the final, significant layer of THCA potency and often a burst of concentrated terpenes, enhancing both effect and flavor/aroma. Using clean, high-micron kief or hash ensures maximum cannabinoid contribution and minimal unwanted plant material, which can taste harsh. The kief must be perfectly dry; any moisture will cause clumping and potential mold issues when combined with the concentrate layer. Low-quality or damp kief ruins the texture, potency, and shelf stability.

Meticulous Component Production & Handling (Drying/Curing/Purging): The preparatory steps for each component are crucial foundations. Improperly dried or cured flower leads to mold or poor structure. Inadequately purged concentrate poses serious health risks. Damp kief leads to spoilage. Meticulous handling throughout prevents degradation or contamination before assembly even begins.

Precise Assembly Technique & Application: How the layers are put together dramatically impacts the final product. Even application of the concentrate ensures consistent potency distribution and provides a uniform surface for kief adhesion. Thorough kief coating ensures maximum potency boost and the signature Moonrock appearance. Rushed or sloppy assembly results in an inconsistent, unattractive product where layers might separate, potency varies wildly, and the overall experience is compromised.

Rigorous Quality Control & Comprehensive Testing: Given the multi-component nature, testing is vital for transparency and safety. Testing each component verifies its individual quality. Testing the final product (especially for potency and residual solvents) provides crucial assurance to retailers and consumers about what they are actually getting in this complex product. Lack of comprehensive testing is a major red flag for Moonrocks.

Appropriate Protective Packaging: The final step in preservation. Moonrocks are vulnerable to physical damage (crushing), sticking, kief loss due to abrasion, and environmental degradation (air, light, moisture). Packaging must be robust enough to protect the structure, minimize surface contact, provide an airtight seal, and ideally shield from light, ensuring the carefully crafted product reaches the consumer in optimal condition.

In essence, producing a high-caliber Exotic THCA Moonrock demands a chain of excellence. Every link – from the initial genetics to the final packaging choice – must be strong to support the integrity and quality of this uniquely potent and complex cannabis creation.

Recommended products

How is the Packaging Itself for Moonrocks Made and Designed?

Packaging Exotic THCA Moonrocks presents a unique set of challenges due to the product’s specific characteristics: density, irregular shape, potential stickiness from the concentrate layer, and a delicate outer coating of kief that needs protection. The packaging design must prioritize preventing physical damage (crushing), minimizing contact that could cause sticking or kief loss, providing an excellent barrier against environmental factors (light, air, moisture) to maintain freshness and potency, and meeting regulatory requirements (child-resistance, labeling) – all while ideally conveying the premium, high-potency nature of the product. Rigid containers are almost always necessary.

Glass Jars

Glass jars, traditionally formed by melting and molding silica sand, soda ash, and limestone, stand out as a premier choice for packaging Exotic THCA Moonrocks. Their inherent rigidity offers maximum protection against physical compression, crucial for maintaining the Moonrock’s shape and preventing the dense structure from being compromised. The smooth, inert surface of glass is advantageous as it minimizes the potential for the sticky concentrate layer or the delicate kief coating to adhere excessively compared to some other materials. Clear glass is often selected by brands wanting to showcase the unique, textured appearance of the Moonrock, highlighting the complete kief coverage and hinting at the quality within, which strongly appeals to consumers purchasing such a visually distinct product. High-quality closures are essential – screw-top or other secure lids fitted with robust, inert liners (like PTFE or multi-layer foam/foil composites) create the necessary airtight seal to lock in the complex aromas derived from the flower, concentrate, and kief, while also preventing moisture exchange that could degrade the product.

Design considerations often involve selecting a jar size that snugly fits the Moonrock(s) with minimal extra space, thereby reducing movement during shipping and handling that could dislodge kief or cause sticking. To further mitigate sticking, some brands employ creative solutions like placing the Moonrock on a small square of parchment paper inside the jar, using jars with specialized non-stick coatings (less common), or designing inserts that cradle the product. The premium weight and feel of glass inherently communicate quality, aligning perfectly with the high-value proposition of Exotic THCA Moonrocks. Furthermore, the smooth exterior provides an excellent surface for high-end labeling or direct printing, allowing brands to convey potency, ingredients, and their craft story effectively. While clear glass offers visibility, UV-protective amber or opaque glass options exist for brands prioritizing maximal long-term preservation over visual display.

Pros:

Superior physical protection against crushing and deformation.

Inert material preserves the complex terpene profile without interaction.

Smooth surface minimizes sticking and kief abrasion compared to rougher materials.

Clear glass offers excellent product visibility, showcasing the unique Moonrock aesthetic.

Capable of providing a truly hermetic seal with high-quality closures.

Premium look, feel, and weight reinforce product value.

Glass is recyclable.

Cons:

Higher packaging cost and weight compared to alternatives.

Susceptible to breakage if dropped or mishandled.

Clear glass offers no protection against UV light degradation.

Careful internal packing (parchment, snug fit) may still be needed to prevent movement and sticking of very tacky Moonrocks.

Biodegradable Jars

These jars, manufactured through molding processes using plant-derived bioplastics (like PLA) or sustainable composite materials (incorporating bamboo, wood fiber, etc.), offer a compelling combination of rigidity and environmental consciousness. Their solid structure provides good protection against the physical crushing of dense Moonrocks, similar to glass. The inherent opacity of most biodegradable materials automatically provides protection from UV light, which can degrade cannabinoids and terpenes over time. The key design challenge lies in engineering a lid and sealing mechanism (often screw-top with a suitable liner) that achieves and maintains a high level of airtightness, crucial for preserving the freshness and preventing moisture from compromising the Moonrock’s texture, especially the kief layer.

The rigidity and light protection are significant benefits for Moonrock preservation. However, the internal surface finish of biodegradable plastics can sometimes be less smooth than glass, potentially leading to slightly more friction and potential for kief abrasion or sticking if the product shifts inside. Brands choosing this option often emphasize sustainability, aligning the high-tech Moonrock product with an eco-friendly packaging message. Ensuring the chosen biodegradable material is sufficiently inert and doesn’t impart any unwanted flavors or odors over time is also a design consideration. While visibility is sacrificed, the protective qualities and environmental angle make it a viable option for certain brands.

Pros:

Good physical protection due to structural rigidity.

Offers an environmentally conscious brand image.

Inherent opacity provides complete UV light protection.

Can be designed with effective airtight seals.

Reduces reliance on petroleum-based plastics.

Cons:

Prevents visual inspection of the Moonrock’s unique appearance.

Internal surface might be less smooth than glass, potentially increasing friction/sticking.

Long-term seal integrity and barrier properties may vary depending on material and design quality.

Often carries a cost premium over conventional plastics.

Effective biodegradation typically requires industrial composting facilities.

Recommended products

-

THCA Smalls

$149.99$256.99 -

THCA Flower – Platinum Line

$49.99$79.99 -

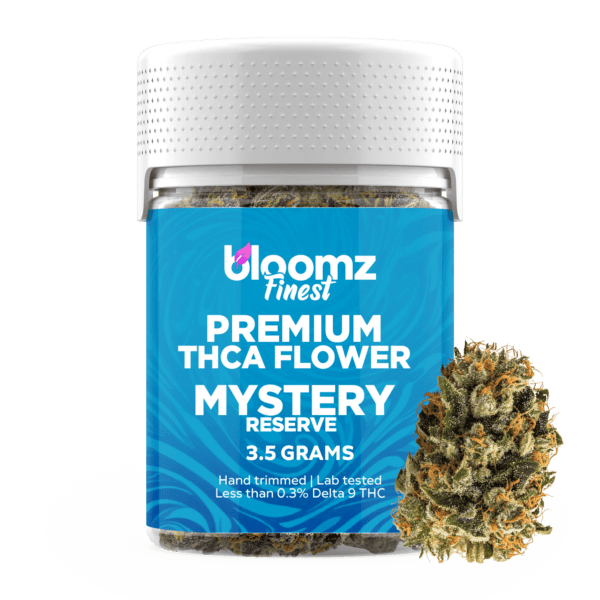

THCA Flower – Mystery Reserve

$41.99$79.99 -

THCA Flower – Exotics – Gold Line

$37.99$69.99

Mylar Bags

Mylar bags are flexible pouches constructed from multiple laminated layers, crucially including a metallic foil layer (usually aluminum) that provides an excellent barrier against oxygen, moisture, and light penetration when the bag is properly heat-sealed. They are lightweight, relatively inexpensive, and offer a large, printable surface area ideal for branding and displaying product information. Common features include resealable zipper closures, tear notches, and bottom gussets for stand-up capability.

Despite their excellent barrier properties, the inherent flexibility of Mylar bags makes them generally unsuitable for packaging premium Exotic THCA Moonrocks. The lack of rigid structure offers virtually no protection against crushing or compression during handling, storage, and transport, which could easily damage or deform the dense Moonrocks. More significantly, the flexible walls allow for constant contact and friction with the Moonrock’s surface. This is highly likely to cause the sticky concentrate layer to adhere firmly to the bag’s interior and the delicate kief coating to be rubbed off and lost to the packaging walls, diminishing potency and ruining the product’s signature appearance and texture. While technologically capable of preserving freshness if undisturbed, the physical interaction within a flexible bag compromises the integrity of this specific product form.

Pros:

Excellent barrier against light, oxygen, and moisture (when properly sealed).

Lightweight and space-efficient for shipping/storage (in theory).

Large surface area available for branding and detailed information.

Can easily incorporate child-resistant zipper closures.

Cons:

Extremely poor physical protection; high risk of crushing/damaging Moonrocks.

High likelihood of the sticky Moonrock adhering to the flexible bag walls.

Significant risk of kief abrasion and loss due to friction.

Makes product removal difficult and potentially messy.

Generally perceived as less premium than rigid jars for high-value items.

Recycling challenges due to multi-material construction.

For Retailers and Consumers: Ways to Identify Properly Made Exotic THCA Moonrocks

Navigating the market for Exotic THCA Moonrocks requires a discerning approach, as the complexity of the product leaves room for variations in quality and authenticity. Properly made Moonrocks are a testament to skill across multiple cannabis disciplines, while poorly made versions can be disappointing or even unsafe. Both knowledgeable retailers curating their premium offerings and consumers seeking a truly potent, high-quality experience need to recognize the indicators that separate genuine craft Moonrocks from inferior imitations. This involves assessing the visible components, considering the source’s reputation, scrutinizing lab data, and understanding the expected characteristics of this unique product.

How Retailers Can Identify Properly Made Moonrocks

Retailers serve as crucial gatekeepers for quality and safety, especially with complex products like Moonrocks. Ensuring the authenticity and quality of their inventory involves several key things:

Verify Manufacturer’s Multi-Disciplinary Expertise: Seek out brands or producers with a proven track record and transparency in all relevant areas: high-quality indoor flower cultivation, clean and compliant concentrate production (including knowledge of different consistencies and solvent purging), and quality kief or hash processing. A manufacturer strong in only one area might struggle with the others. Ask detailed questions about their sourcing and production methods for each component.

Demand Comprehensive, Batch-Specific COAs: Certificates of Analysis are absolutely critical and non-negotiable for Moonrocks due to their multi-component nature. Insist on seeing lab reports for the final assembled product that confirm:

Potency: Extremely high total THCA and total cannabinoid percentages (often 40-60%+), alongside legally compliant Delta-9 THC levels (<0.3%).

Full Safety Panel: Passing results for pesticides, heavy metals, and microbial contaminants (yeast, mold, bacteria). These tests should ideally reflect the cleanliness of all input components.

Residual Solvent Testing: This is paramount. The COA must show passing results (below legal action limits) for any solvents potentially used in the concentrate production phase (e.g., butane, propane, ethanol, pentane, heptane). Absence of this specific test is a major red flag indicating potential safety risks.

Conduct Rigorous Sensory and Visual Evaluations: Carefully examine the product:

Visual Inspection: Moonrocks should appear as dense, reasonably uniform orbs completely covered in a thick, consistent layer of kief. The kief should look like fine trichome powder (golden, tan, or light blonde), not green plant matter. The underlying bud structure should seem solid, not flimsy. The concentrate layer shouldn’t be visibly pooling, dripping, or excessively thick and uneven. Look for consistency across units within a batch.

Aroma Assessment: The smell should be potent and complex, reflecting a blend of the base flower’s terpenes amplified and complemented by the terpenes present in the kief (and potentially the concentrate, if terpene-rich like rosin or live resin was used). It should smell distinctly and intensely like high-quality cannabis, with no detectable chemical, solvent, or off-putting odors.

Tactile Assessment (Handle Gently): Moonrocks should feel dense and solid when gently handled. The surface will likely be somewhat tacky or sticky due to the concentrate but shouldn’t feel overly wet, greasy, or unstable. The kief layer should adhere well, although minimal shedding upon handling is normal. Avoid products that feel light/airy, crumble easily, or where the kief seems sparsely applied or falls off readily.

Evaluate Packaging Standards: Assess if the packaging is appropriate for protecting such a delicate and potentially sticky product. Rigid containers (preferably glass jars) that minimize movement and prevent crushing are strong indicators of a producer who values product integrity. Poor packaging choices (like Mylar bags) may suggest less attention to quality preservation.

How Consumers Can Identify Properly Made Exotic THCA Moonrocks

Consumers seeking the powerful experience of Exotic THCA Moonrocks should look for these specific signs to ensure they are getting value and reliability for this premium product category:

Brand Reputation and Transparency: Opt for brands known for producing high-quality flower and concentrates. Look for brands that provide information about the strains used for the flower core, the type of concentrate utilized, and potentially the source of the kief. Transparency often correlates with quality. Patronize reputable, licensed dispensaries.

Detailed Visual Inspection: Examine the Moonrock closely (ideally through clear packaging like a glass jar). It should look like a solid bud thoroughly coated in a generous layer of kief that resembles fine sand or powder, not green dust. You shouldn’t see large patches of exposed flower or obvious globs of wet-looking concentrate. It should look like a cohesive, well-constructed unit.

Potent and Clean Aroma: Upon opening the package, the smell should be strong, complex, and inviting – a rich cannabis aroma combining flower and kief notes. Any hint of chemicals, solvents, hay, or mildew is a definite warning sign to avoid the product.

Texture and Density: While you might not handle it extensively before purchase, it should look dense and solid. Post-purchase, it should hold together well when handled gently for breaking apart (do not use a grinder!).

Availability of Lab Reports (COAs): Look for QR codes or ask the dispensary for test results. Confirm very high THCA/total cannabinoid potency, Delta-9 compliance, and crucially, check for passing safety tests, especially for residual solvents. If testing information is unavailable or incomplete, be cautious.

Appropriate Packaging: Favor Moonrocks sold in rigid jars (glass is best) that protect the product from being crushed and minimize sticking. Be wary of Moonrocks sold loosely in bags.

Premium Price Point: Understand that authentic, high-quality Moonrocks are costly to produce due to the multiple premium ingredients and labor involved. Expect a significantly higher price than standard flower; unusually cheap Moonrocks are likely made with subpar components or lack proper testing.

Responsible Consumption: Remember that Moonrocks are exceptionally potent. Start with a tiny amount – much smaller than a typical serving of flower – to assess your tolerance. Break them apart gently by hand (grinders will become a sticky mess) and they are often best consumed in a glass pipe or bong rather than rolled.

Crafting Something So ‘Moonstruck’ as Moonrocks Truly is an Intricate Process!

The very existence of Exotic THCA Moonrocks pushes against the familiar boundaries of the cannabis experience, standing as potent artifacts from the frontiers of horticultural and chemical exploration. They represent more than just combined ingredients; they embody a relentless human curiosity, a drive to interact with the plant’s potent essence in novel, almost audacious ways. Gazing upon these densely coated orbs invites contemplation – not just of the intricate journey from seed to sale detailed before, but of the sheer inventive spirit required to envision and then meticulously construct such a unique item. Holding one is like holding a tangible piece of cannabis innovation, a conversation starter crafted from dedication and a profound appreciation for the plant’s versatile potential, destined to leave an impression long after the encounter.