In the ever-expanding universe of cannabis products, the pre-roll holds a special place – the epitome of convenience, ready for enjoyment straight out of the package. But what happens when that convenience converges with the peak of cannabis cultivation? Enter the Exotic THCA Pre-Roll. This isn’t just any pre-rolled joint; it’s a carefully crafted experience starting with sought-after, meticulously grown exotic flower, rich in THCA and bursting with unique terpenes, transformed into a perfectly smokeable format.

It promises the accessibility of a pre-roll combined with the quality typically reserved for top-shelf jars. How is this feat achieved? What journey does rare, exotic flower undertake to become such a refined, ready-to-light indulgence? Let’s ignite our curiosity and explore the detailed process behind the creation and packaging of Exotic THCA Pre-Rolls.

To Buy THCA Exotic Pre-Rolls Click Here

A Quick Insight into What THCA Pre-Rolls are

Exotic THCA pre-rolls represent the apex of convenience meeting connoisseurship. These aren’t your standard pre-rolls; they are filled with cannabis flower derived from “exotic” strains, a term typically reserved for cultivars boasting rare genetics, exceptionally unique terpene profiles resulting in uncommon aromas and flavors, striking visual appeal, or those grown using specialized, craft cultivation techniques. These strains stand apart from the usual offerings, often carrying a reputation for specific and pronounced effects. Like other THCA products, the primary cannabinoid in the raw flower is tetrahydrocannabinolic acid (THCA) – a non-psychoactive precursor to Delta-9 THC.

Now, the transformation crucial to the experience occurs through heat via decarboxylation – the simple act of lighting the pre-roll converts the abundant THCA into Delta-9 THC, unlocking the powerful potential effects associated with high-THC cannabis. So, essentially, exotic THCA pre-rolls offer a compliant pathway to enjoy some of the most exclusive and potent cannabis flower on the market, packaged in the most convenient form possible. They utilize legally defined hemp-derived flower, celebrated for its extremely high THCA concentration and unique characteristics, ensuring adherence to regulations while maximizing the potential for a top-tier experience. Consumers seek them out not just for the ease of use, but for the chance to explore rare flavors, captivating aromas, and the potentially heightened levels of enjoyment that come from truly special, high-potency cannabis cultivars selected for their exceptional qualities.

What is Initially Needed to Make Exotic THCA Pre-Rolls?

Producing pre-rolls that live up to the “Exotic THCA Pre-Rolls” name requires a foundation built on uncompromising quality and specialized manufacturing capabilities. It begins with securing truly exceptional cannabis flower and extends through every piece of equipment and every procedural step, ensuring the unique characteristics of the exotic source material are preserved and delivered consistently. This endeavor demands a significant investment in premium inputs and precise processes. Below is an in-depth look at the essential prerequisites:

Premium Exotic THCA Flower: The defining ingredient, setting the standard for the entire product. This necessitates:

Elite Genetics: Again, sourcing specific, named exotic strains known for their unique and highly desirable terpene profiles, high THCA production, visual appeal (even when ground), and smooth smoking characteristics. These are often indoor-grown, connoisseur-grade cultivars.

Top-Tier Cultivation Source: Flower must come from meticulous indoor (or potentially top-tier greenhouse) operations capable of consistently producing clean, potent, terpene-rich exotic strains that meet strict low-Delta-9 THC compliance.

Whole Flower Preference: While some THCA pre-rolls use trim, “exotic” designation strongly implies the use of ground whole flower (cured buds) to ensure the full spectrum of cannabinoids and terpenes from the chosen strain is present, maximizing flavor and effect potential. High-quality small buds (“smalls”) from exotic harvests might also be used.

Perfect Cure & Moisture Content: The flower must be expertly dried and undergo a patient, thorough cure (weeks or months) to develop optimal smoothness and flavor. Moisture content must be precisely controlled (around 10-12%) before grinding to ensure ideal particle size and burn characteristics.

Precision Cannabis Grinding Equipment: How the exotic THCA pre-rolls are ground significantly impacts the final product’s burn and trichome preservation:

Trichome Preservation Focus: Grinders that minimize heat generation and physical agitation are preferred. Industrial burr grinders or specialized low-RPM shredders are often chosen over high-speed blade grinders, which can pulverize trichomes and create too much fine dust.

Consistent Particle Size: The goal is a uniform, fluffy consistency – not powder, not large chunks – that allows for even airflow when packed. Screens within the grinder help achieve this target consistency batch after batch.

Connoisseur-Grade Rolling Papers/Cones & Filters: The vessel must complement, not detract from, the premium THCA flower:

Premium Papers: Ultra-thin, unbleached papers made from high-quality materials like hemp, rice, or flax are preferred for their minimal impact on taste and clean burn. Brands known for quality are often selected. Pre-formed cones ensure consistent shape and size.

High-Quality Filters/Tips: Beyond standard paper crutches, exotic pre-rolls often feature premium tips made from materials like wood, glass, or ceramic, enhancing the aesthetic and potentially providing a cooler draw. The filter must be well-constructed and appropriately sized for optimal airflow.

Custom Branding (Optional): Cones or papers might be custom printed with the brand’s logo for an added touch of exclusivity.

Precision Filling & Compacting Machinery: Achieving a flawless roll consistently requires specialized equipment:

Advanced Filling Systems: While knockboxes can be used, higher-end semi-automated or fully automated machines offering greater control over fill weight and density distribution are often employed for premium products. These systems aim for extremely tight weight tolerances.

Optimized Compaction: Achieving the perfect density is crucial for exotic flower – ensuring an even burn that showcases the flower’s quality without restricting airflow. Compaction methods are carefully calibrated for the specific characteristics (density, moisture) of the ground exotic flower.

Meticulous Finishing Station & Tools: The final touches reflect the product’s premium nature:

Expert Closing Techniques: Ends are often finished with aesthetically pleasing folds (like a Dutch crown) or precise twists, ensuring no spillage and a polished look. This may be done by skilled personnel even if filling is automated.

High-Precision Scales: Necessary for strict weight verification of each premium THCA pre-rolls.

Magnified Inspection: Quality control often involves visual inspection under magnification to check for any imperfections in the roll or visible material quality.

Immaculate & Controlled Production Environment: The entire grinding, filling, and packaging process must occur in a cleanroom-like environment with controlled temperature and humidity to:

Prevent any contamination (dust, microbes) of the premium flower.

Preserve volatile terpenes.

Maintain optimal material handling conditions.

Ensure consistent machine performance.

(Optional but Common – Premium Infusion Components): Exotic THCA pre-rolls are frequently infused to further enhance potency and uniqueness:

High-Quality, Strain-Specific/Complementary Concentrate: Options include solventless hash rosin, live resin sauce/batter, high-terpene full-spectrum extracts (HTFSE), or pure THCA distillate. The concentrate must be low Delta-9, tested, and chosen to complement the base flower’s profile.

Clean, Potent Kief: Ideally derived from the same or complementary exotic strains, finely sifted and tested for purity and potency, used for external coating.

Precision Infusion Equipment/Station: Tools and methods for accurately applying the infusion, whether mixing internally, injecting a core, painting the exterior, or evenly coating with kief, without compromising the pre-roll’s structure or burn quality.

Sourcing these premium materials and investing in the specialized equipment and controlled environments needed for production are fundamental to creating authentic Exotic THCA Pre-Rolls.

Recommended products

Understanding the Entire THCA Pre-Rolls Process

The journey of transforming top-shelf Exotic THCA Pre-Rolls into a perfectly crafted pre-roll is a blend of careful preparation, precision manufacturing, and often, artistic infusion techniques. It’s about taking exceptional starting material and ensuring its quality is not only preserved but optimally presented in a convenient, ready-to-use format. The process demands meticulous attention at every stage to deliver the smooth burn, rich flavor, and potent experience expected from an “exotic” label. Here’s a walkthrough of how they are typically made:

Sourcing & Cultivating Premium Exotic THCA Flower: The process originates with securing the star ingredient. This involves either dedicated indoor cultivation of specific, named exotic strains known for high THCA, unique terpene profiles, and desirable smoking characteristics, or meticulous sourcing of compliant, top-shelf flower from trusted cultivators. Only the best buds, often whole flower rather than just trim, are selected.

Optimal Curing, Preparation, and Quality Check: The selected flower must be perfectly cured (a process taking weeks to months) to ensure smoothness and full flavor development. Prior to grinding, buds are carefully inspected, large stems removed by hand, and the moisture content verified to be within the ideal range (typically 10-12%) for grinding and burning.

Precision Grinding & Homogenization: The cured exotic THCA pre-roll is carefully ground using equipment designed to produce a uniform, fluffy consistency while minimizing trichome damage and heat generation. Achieving the right particle size is critical – too fine restricts airflow, too coarse burns unevenly. For larger batches, ground material may be gently homogenized to ensure consistency in potency and character throughout the run.

Preparing Premium Cones/Papers: High-quality pre-rolled cones, often featuring premium filter tips (glass, wood), are loaded into the filling apparatus (trays for knockboxes or magazines for automated systems). Care is taken to ensure cones are pristine and correctly positioned.

Accurate Filling & Perfect Compaction: This stage requires precision machinery or highly skilled manual techniques:

Weighing & Filling: An exact weight of the ground exotic THCA flower is dispensed into each cone. Precision scales integrated into automated systems or used diligently with manual/semi-auto methods ensure consistency.

Settling & Compacting: Vibration and/or tamping mechanisms are used to settle the flower and compact it to a precise, predetermined density. This step is meticulously calibrated based on the specific flower’s characteristics (density, moisture) to achieve optimal airflow for a smooth draw and prevent canoeing or rapid burning. This is often where craft quality is most evident.

Optional Premium Infusion Integration: If creating infused exotic pre-rolls, this step adds complexity:

Internal Infusion: Powdered THCA isolate or precisely dosed liquid concentrates (like terpene-rich live resin or hash rosin) might be evenly blended with the ground flower before filling. Alternatively, specialized machinery can inject a line or core of concentrate into the center of the pre-roll during the filling process, requiring careful calibration to avoid clogging or uneven distribution.

External Coating: The finished, non-infused pre-roll is carefully coated on the outside. A thin, even layer of a sticky, high-THCA concentrate (like slightly warmed hash rosin or distillate) is meticulously applied (e.g., painted on with a brush), ensuring it doesn’t oversaturate the paper. Immediately afterward, the sticky pre-roll is gently rolled in high-quality, strain-complementary kief until fully encrusted. This requires significant dexterity and care.

Meticulous Finishing/Closing: The open end of the filled pre-roll is expertly closed to secure the contents and provide a polished look. Common methods for exotic pre-rolls include a precise twist or, more often, a carefully folded “Dutch crown,” which offers a flat surface ideal for lighting. This step is often done by hand even in semi-automated processes to ensure aesthetic perfection.

Rigorous Quality Control: Each exotic pre-roll, or a statistically significant sample, undergoes multiple checks:

Weight Consistency: Verifying adherence to the target weight.

Visual & Structural Inspection: Checking for perfect construction – no tears, wrinkles, voids, or loose spots. Ensuring the filter is straight and secure. Assessing the neatness of the closed tip. For infused rolls, checking the uniformity and quality of the coating or signs of internal infusion.

Density/Draw Assessment: Ensuring the pack density allows for a comfortable draw.

Final Laboratory Testing: Sending representative samples of the finished batch (including infused versions) for final confirmation of potency (THCA, Delta-9), safety (contaminants, residual solvents if applicable), and potentially terpene profile validation.

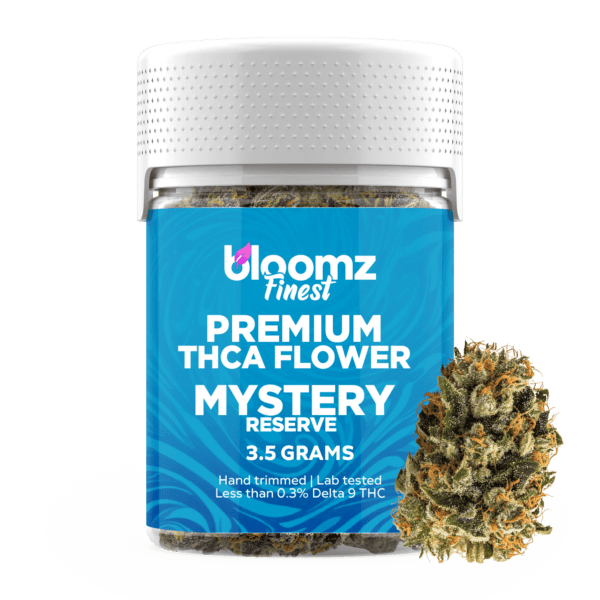

Premium Packaging: Approved Exotic THCA Pre-Rolls are carefully placed into their final retail packaging (e.g., individual tubes, premium jars) using methods that prevent damage and maintain their pristine condition until they reach the consumer.

Why is Each Step Vital to the THCA Pre-Rolls Making Process Anyways?

Creating an Exotic THCA pre-roll that genuinely delivers a premium experience requires meticulous execution at every stage. The “exotic” label carries high expectations for quality, flavor, smoothness, and effect, meaning any compromise along the production chain can disproportionately impact the final product’s value and reputation. Each step/phase is a critical link ensuring the essence of the high-end starting material is successfully translated into the convenient pre-roll format:

Premium Exotic Flower Selection & Quality: This is non-negotiable. The exotic flower is the product’s soul. Its genetic potential, cultivation quality, terpene profile, and proper cure dictate the core sensory experience – the taste, aroma, and nuanced effects. Using anything less than exceptional, compliant flower invalidates the “exotic” claim from the start.

Optimal Cure & Preparation: An improper cure results in harshness and poor flavor, regardless of the strain’s quality. Removing stems prevents uneven burning and bitterness. Achieving the precise moisture content is crucial for the subsequent grind – impacting particle size, consistency, and ultimately, how well the pre-roll burns.

Precision Grinding: The consistency of the grind is paramount for airflow and combustion. Too fine, and the roll becomes tight, hard to draw, and potentially harsh. Too coarse, and it packs unevenly, burns too quickly, and is prone to canoeing. A uniform, fluffy grind achieved through quality equipment is essential for that smooth, even burn expected from a premium THCA product.

High-Quality Papers/Cones & Tips: The vessel matters. Thin, clean-burning papers ensure the flavor focus remains on the exotic flower’s terpenes, not on paper taste. Premium filter tips (glass, wood) enhance the tactile experience, contribute to proper airflow, and signal quality to the consumer. Poor quality papers or filters detract significantly from the premium experience.

Flawless Filling & Compaction: This manufacturing step directly translates to smoking performance. Inconsistent filling leads to variable weights. Improper compaction – too tight or too loose – is the primary cause of poor draw and uneven burning (canoeing), frustrations that instantly undermine the perception of quality, regardless of how good the flower inside is. Precision here is key to enjoyment.

Expert Infusion (If Applicable): For infused exotic pre-rolls, the quality and application method are critical. Using clean, potent, safe, and complementary concentrates/kief is vital. Applying the infusion evenly ensures consistent potency and prevents burn issues or messiness. Poor infusion can easily ruin both the flavor and the structural integrity of the THCA Pre-Roll

Meticulous Finishing: A neatly finished tip prevents spillage, ensures easier lighting, and contributes to the overall polished, professional appearance expected of an exotic product. Sloppy finishing detracts from the perceived quality.

Stringent Quality Control: QC catches manufacturing errors (weight variance, poor compaction, flaws) and ensures consistency across the batch. Final lab testing provides essential verification of potency, compliance, and safety (contaminants, residual solvents), building trust and validating the premium claims.

Protective & Premium Packaging: Exotic pre-rolls represent a significant investment by both the producer and consumer. Packaging must adequately protect these relatively fragile items from crushing, preserve freshness and terpene profiles with an airtight seal, meet compliance standards, and visually reflect the premium quality contained within. Damaged or stale pre-rolls due to poor packaging negate all upstream efforts.

In essence, crafting an Exotic THCA pre-rolls requires treating every step with the same level of care and precision demanded by the premium flower it contains. It’s about preserving and perfectly presenting that exotic quality in a convenient form.

How is the Packaging Itself for THCA Pre-Rolls Made and Designed?

Packaging for exotic THCA pre-rolls plays a crucial role in protecting the product’s integrity, preserving its freshness and unique terpene profile, ensuring regulatory compliance, and communicating the premium, often strain-specific nature of the contents. Given that exotic pre-rolls typically contain high-value flower and may feature premium construction or infusions, the packaging often leans towards higher-quality materials and designs that offer superior protection and shelf appeal compared to standard market offerings. Rigidity to prevent crushing, effective sealing against air and moisture, and child-resistant features are paramount design considerations.

Glass Jars

Glass jars chosen for exotic THCA pre-roll multi-packs are produced from high-purity molten glass (silica sand base), molded into often thick-walled, aesthetically pleasing shapes. The manufacturing process ensures an inert, impermeable container that won’t interact with or taint the delicate terpene profiles of the exotic flower. Designs frequently feature wide mouths for easy access and often utilize crystal-clear glass to showcase the pre-rolls themselves – potentially highlighting unique filter tips, perfectly uniform construction, or even visible infusion coatings (like kief). The focus is on conveying luxury and allowing visual confirmation of quality. Lids are a critical design element, typically high-quality screw-on caps (metal, wood, premium plastic) fitted with advanced liners (multi-layer foam/foil, PTFE) engineered to create a hermetic seal, locking in freshness, preventing terpene loss, ensuring odor containment, and protecting against moisture ingress.

The inherent rigidity of glass provides the best possible protection against physical damage for multiple pre-rolls stored together. The premium feel and clarity directly support the “exotic” positioning. Child-resistant closure mechanisms are seamlessly integrated into high-end lid designs. While representing a higher packaging cost and weight, glass jars are often preferred by brands seeking to present their exotic THCA pre-rolls as a top-shelf, connoisseur product where preservation and presentation are paramount. The smooth surface is ideal for minimalist, elegant labeling or direct printing detailing the exotic strain, potency, and terpene information.

Pros:

Maximum physical protection for multiple pre-rolls.

Completely inert, preserving the most delicate terpene profiles.

Superior airtight sealing potential for optimal freshness and odor control.

Excellent product visibility through clear glass showcases premium rolls.

High-end, premium aesthetic reinforces product value.

Recyclable container material

Cons:

Highest cost among the options.

Breakable and heavier, increasing shipping costs/risks.

Clear glass offers no UV protection (mitigated by labels or secondary packaging).

Reliant on high-quality lid/liner combination for seal integrity.

Biodegradable Jars

These jars are manufactured using molding processes (injection or compression) with sustainable materials like PLA (polylactic acid from plant starches) or advanced composites incorporating materials like hemp fiber, wood pulp, or baboo. The design goal is to create a rigid container that offers robust physical protection comparable to traditional plastic jars, ensuring the exotic THCA pre-roll inside are safe from crushing. Due to the nature o the materials, these jars are typically opaque, which provides inherent, full protection from UV light degradation – a significant advantage for preserving cannabinoids and terpenes over long periods. Considerable engineering effort focuses on the lid design (usually screw-on) and the selection of appropriate liner materials to achieve a reliable airtight seal crucial for maintaining freshness and containing the potent aroma of exotic strains.

The primary appeal is the combination of effective protection with a strong sustainability narrative, which resonates with certain consumer segments, even within the luxury market. While opacity hides the THCA Pre-Rolls, it guarantees light protection. The design can often be customized with unique colors or textures derived from the biodegradable materials themselves, offering distinct branding possibilities. Child-resistant closures are readily integrated. Biodegradable jars represent a choice for exotic brands aiming to balance premium product quality with environmental responsibility, provided the sealing performance meets the high demands for preserving exotic terpene profiles.

Pros:

Good physical protection due to rigid structure.

Strong environmental and sustainability appeal.

Inherent opacity provides complete UV light protection.

Can be designed with effective airtight seals.

Offers unique aesthetic possibilities based on materials.

Cons:

Prevents visual inspection of the premium pre-rolls.

Long-term inertness and barrier properties compared to glass may vary by specific material.

Can be more expensive than standard plastic, sometimes approaching glass costs.

Effective biodegradation typically requires industrial composting facilities.

Seal quality is dependent on precise manufacturing and liner choice.

Tubes (Plastic, Glass, or Biodegradable)

Pre-roll tubes, designed for single units, are manufactured via methods suited to their material. Plastic tubes (often PP or PET) typically use extrusion or injection molding for efficient mass production of rigid or semi-rigid cylinders. Glass tubes are formed from heated glass, offering superior inertness and clarity for a very premium single-unit presentation. Biodegradable tubes can be molded from PLA or similar resins. The core design principle is a snug-fitting cylinder that prevents the single exotic flower pre-roll from bending or breaking during transport and handling. Closures are diverse, ranging from simple plugs (less common for exotic) to secure snap-caps or, more typically, certified child-resistant push-and-turn or squeeze-style caps, often incorporating liners or tight tolerances for an effective seal.

Tubes excel at providing discrete portability and excellent protection for individual, high-value exotic THCA pre-rolls. They can be designed to be airtight or near-airtight, preserving freshness and containing odor effectively for that single unit. Clear tubes (glass or plastic) allow consumers to see the quality of the individual roll, including premium papers or tips, while opaque tubes (plastic or biodegradable) offer light protection. While offering less overall branding space than jars, tubes can be directly printed, labeled, or utilize premium materials like thick glass or custom-colored biodegradable resins to convey exotic quality. They are an extremely popular choice for single-unit sales of premium and exotic pre-rolls.

Pros:

Excellent physical protection for individual pre-rolls.

Highly portable and convenient for single use.

Can provide very good airtightness and odor control

Easily incorporates effective child-resistance.

Available in premium materials (glass) or sustainable options (biodegradable).

Clear options allow visibility of the single roll.

Cons:

Designed for single use, potentially increasing waste per unit (especially plastic).

Limited surface area for branding/information compared to multi-pack jars.

Higher per-pre-roll packaging cost than multi-packs.

Plastic tubes might cause static that attracts kief if rolls are heavily coated/infused.

Seal quality varies significantly based on cap design.

Recommended products

For Retailers and Consumers: Ways to Identify Properly Made THCA Pre-Rolls

Distinguishing a truly premium Exotic THCA Pre-rolls from a standard one, or worse, a poorly disguised low-quality offering, requires attention to detail beyond the “exotic” label itself. Authenticity lies in the verifiable quality of the source flower, the precision of the manufacturing, the choice of materials, and the overall sensory experience. Both discerning retailers building a top-tier menu and consumers seeking a genuinely elevated pre-roll experience need to know the hallmarks of quality that justify the “exotic” designation and associated price point.

How Retailers Can Identify Properly Made THCA Pre-Rolls

Retailers sourcing exotic pre-rolls must act as critical evaluators, ensuring the products meet the high expectations associated with the category by utilizing the following strategies:

Scrutinize Source & Genetics Claims: Partner with reputable brands known for cultivating or sourcing genuine exotic strains and using high-quality THCA flower (ideally whole flower) in their pre-rolls. Demand transparency about the specific strain(s) used and verify their reputation. Be wary of vague claims.

Analyze Comprehensive COAs: Certificates of Analysis are crucial. Look beyond basic potency:

Potency: Confirm high THCA, low Delta-9 THC.

Terpene Analysis: This is key for exotic validation. Look for a detailed terpene profile with significant percentages (often >1.5-2% total terpenes) and dominant terpenes consistent with the claimed exotic strain’s known profile.

Safety: Ensure passing results for pesticides, heavy metals, microbials. If infused, verify residual solvent testing for the concentrate used.

Conduct Meticulous Visual & Physical Inspections:

Construction Quality: THCA Pre-Rolls should be flawless – perfectly cylindrical, uniformly packed (firm but not hard), with no visible runs, gaps, or looseness near the filter. The tip should be expertly closed (e.g., perfect Dutch crown).

Materials: Assess the quality of the paper (thin, premium feel) and the filter tip (e.g., glass, wood, or well-made custom paper tip).

Flower Visibility (If Possible): Through clear tubes or by carefully examining the tip, look for ground material that appears vibrant (not brown/dull), potentially showing visible trichomes, and lacks excessive stem fragments.

Infusion Assessment: If infused, check for even kief coating (no bald spots), consistent oil application (no major dark spots or leaks on the paper), or other indicators

Evaluate Aroma: Even through packaging, a high-quality exotic pre-roll should often exude a noticeable aroma characteristic of its specific strain. Upon opening, the scent should be potent, clean, and match the expected unique profile (fruity, gassy, candy-like, etc.).

Perform Burn Tests (Crucial for Samples): The ultimate test. A well-made exotic THCA pre-rolls should: light easily, burn exceptionally evenly with no canoeing, offer a smooth, comfortable draw, taste clean and distinctly of the strain’s terpenes without harshness, and produce light gray/white ash.

Assess Packaging Presentation: Look for premium packaging (quality tubes, jars) that protects the product well, seals effectively, meets compliance, and reflects the exotic positioning through design and detailed labeling.

How Consumers Can Identify Properly Made THCA Pre-Rolls

Consumers seeking an authentic exotic pre-roll experience should look for multiple indicators of quality, specifically focusing on:

Brand Reputation & Strain Specificity: Choose brands known for quality and transparency. Look for pre-rolls that clearly state the specific exotic strain used, rather than generic labels. Information about the flower source (e.g., “indoor whole flower”) is a plus.

Visual Examination: Inspect the THCA pre-roll (ideally in a clear tube or jar). Does it look expertly crafted? Is the paper thin and high-quality? Is the filter tip premium (glass/wood)? Does it look evenly packed? If infused, does the kief coat look generous and powdery, or the oil application neat?

Aroma: A key indicator. Upon opening, the pre-roll should release a strong, appealing aroma that matches the description of the exotic strain (e.g., intense citrus, fuel, candy, unique floral notes). A weak or generic smell suggests lower quality.

The Burn Experience: This is where quality truly shows. An exotic pre-roll should burn slowly, evenly, and smoothly, allowing you to savor the distinct flavors of the strain without harshness or requiring constant relights. Watch for canoeing – a sign of poor packing.

Packaging Quality: Look for packaging that protects the THCA pre-roll from damage (rigid tubes or jars are best) and appears well-sealed to maintain freshness. Premium packaging often signals a premium product.

Lab Report Access: Check for QR codes or other ways to access test results. Verify high THCA, low Delta-9, and safety checks. Pay attention to the listed terpene profile – does it look impressive and match the strain’s reputation?

Price Point: Genuine exotic pre-rolls made with premium indoor flower (and potentially infusions) carry a significant price premium over standard pre-rolls. Expect to pay more; be skeptical of prices that seem too good to be true for an “exotic” product.

Making Those Exotic THCA Pre-Rolls Can Be an Intricate Process Indeed!

The journey culminating in an Exotic THCA Pre-Roll showcases a remarkable fusion of top-tier cultivation, precision manufacturing, and often, advanced infusion techniques. It’s a process demonstrating that even the most convenient cannabis format can achieve heights of quality and sophistication when approached with dedication and the right resources.

Translating the nuanced terpene profiles and potent effects of rare, exotic flower into a perfectly burning, flawlessly constructed pre-roll requires meticulous care at every juncture, from the living plant to the final packaged product. These creations stand as proof that convenience need not come at the expense of connoisseurship, offering a ready-to-enjoy passport to the pinnacle of cannabis craft.