Step inside the world of indoor cannabis cultivation, and you enter a realm where science meets horticulture in pursuit of perfection. Unlike the unpredictable nature of outdoor growing, indoor environments offer cultivators near-total control, allowing them to meticulously orchestrate every variable—from the precise spectrum of light to the parts-per-million of nutrients in the water. This level of control enables the production of THCA flower with remarkable consistency, potency, and aesthetic appeal. But how exactly is this carefully managed process carried out, transforming a tiny seed or clone into the pristine, potent buds found on dispensary shelves? Let’s illuminate the journey of indoor THCA flower, from its controlled beginnings to its final packaged form.

To Buy Indoor THCA Flower Click Here

A Quick Insight into What Indoor THCA Flower is

Indoor THCA Hemp Flower refers to cannabis cultivars legally defined as hemp (containing less than 0.3% Delta-9 THC by dry weight in its raw state) that’re specifically bred and cultivated indoors to maximize their tetrahydrocannabinolic acid content. Real quick too, for those who don’t know, THCA is the natural precursor to the well-known intoxicating compound Delta-9 THC; it only converts to THC upon heating. The “indoor” designation is crucial, signifying that the plants were grown entirely within a controlled indoor environment, shielded from the unpredictable elements of outdoor cultivation.

Cultivating hemp flower indoors grants growers precise mastery over critical environmental variables. This includes controlling light cycles and spectrums, managing temperature and humidity levels meticulously, optimizing airflow and CO2 concentration, and fine-tuning nutrient delivery through methods like hydroponics or carefully managed living soil. This high degree of control allows cultivators to nurture the plants in ideal conditions throughout their lifecycle, minimizing stress and maximizing the expression of desirable traits like high THCA production, rich terpene profiles (responsible for aroma and flavor), dense bud structure, and abundant trichome coverage (the frosty crystals containing cannabinoids and terpenes).

Basically, the controlled environment leads to greater consistency from batch to batch, enhanced visual appeal (“bag appeal”), better preservation of delicate terpenes, and often, higher achievable potency levels. It’s a product category favored by consumers seeking reliable quality, pronounced effects, and a premium sensory experience derived from meticulously cultivated hemp compliant with federal law.

What is Initially Needed to Make Indoor THCA Flower?

Embarking on the cultivation of high-quality Indoor THCA flower necessitates a significant upfront investment in specialized equipment, careful planning, and a foundational understanding of controlled environment agriculture. Unlike growing outdoors where nature provides many core elements, indoor cultivation demands the artificial recreation and precise management of every environmental factor crucial to plant life. This meticulous preparation is key, as the quality of the setup directly influences the ability to achieve consistent, potent, and visually appealing results. Creating this optimized environment is the first critical step towards producing top-tier indoor flower, as the requirements are:

Suitable Genetics: The foundation of any successful grow is the genetic material itself. For indoor cultivation, stability and uniformity are paramount. Growers seek strains that exhibit predictable growth patterns, allowing for efficient space management and synchronized batch handling. Genetics prone to significant variation can complicate canopy management and harvest timing. Equally important is selecting cultivars bred or known to thrive under artificial lighting and controlled conditions – some strains simply perform better indoors than others. Key selection criteria include:

High THCA Potential: The primary goal is flower rich in THCA. Genetics must possess the inherent capability to produce high concentrations.

Desirable Terpene Profiles: Beyond potency, unique and appealing aromas/flavors derived from specific terpenes are highly sought after.

Manageable Structure: Indoor spaces often have height limitations. Ideal strains are typically less prone to excessive vertical stretching (“bolting”) during flower, exhibit strong lateral branching, and possess a favorable bud-to-leaf ratio, simplifying trimming.

Predictable Flowering Time: Consistent flowering periods allow for accurate scheduling and efficient facility workflow.

Pest/Disease Resistance: While environment control helps, inherent genetic resistance provides an additional layer of security. Reputable breeders specializing in indoor-optimized strains are often the preferred source for seeds or clones, providing greater assurance of genetic stability and performance.

Dedicated Indoor Space: The physical location must be purpose-fit for cultivation, offering complete control over the internal environment. This space, whether a compact grow tent for personal use or a large-scale commercial facility, absolutely must feature:

Absolute Light-Proofing: Cannabis flowering is triggered by specific photoperiods. Any light intrusion during the critical 12-hour dark cycle can disrupt hormonal processes, causing stress, reversion to vegetative growth, delayed flowering, or even inducing hermaphroditism (producing male flowers), which ruins a sinsemilla (seedless) crop. This requires sealing all light leaks from doors, vents, windows, and even indicator lights on equipment.

Sealed & Cleanable Environment: A sealed space allows for precise control over air exchange, temperature, humidity, and CO2 levels, while also acting as a barrier against external pests and pathogens. Surfaces should be non-porous, smooth, and easy to sanitize between crop cycles – common choices include epoxy-coated concrete floors, specialized washable wall paints, or panels like FRP (Fiber-Reinforced Plastic). Maintaining scrupulous hygiene is fundamental to preventing pest and disease outbreaks in an enclosed environment. Airflow design within the sealed space is also critical to prevent stagnant air pockets.

Sufficient & Appropriately Zoned Space: The area must accommodate the planned number of plants with adequate spacing for airflow and light penetration to the lower canopy. Beyond plant space, room is needed for essential equipment (lights and ballasts/drivers, fans, dehumidifiers, nutrient reservoirs, filters), potentially separate zones for different growth stages (propagation/cloning, vegetative, flowering, drying/curing), and safe, efficient working access for personnel to monitor, maintain, and harvest the crop. Poor space planning leads to inefficiencies and potential quality issues.

Precision Environmental Controls: This sophisticated system is the engine driving indoor cultivation, allowing growers to simulate ideal conditions 24/7:

Horticultural Lighting: Providing the right quality and quantity of light is non-negotiable. High-Intensity Discharge (HID) lights, like Metal Halide (MH, typically used for veg due to blue-rich spectrum) and High-Pressure Sodium (HPS, favored for flowering with its red-rich spectrum), are traditional choices but generate significant heat and are less energy efficient. Modern Light Emitting Diodes (LEDs) designed specifically for horticulture are increasingly dominant due to their energy efficiency, lower heat output, and often tunable spectrums, allowing optimization for different growth phases. Key considerations include achieving target Photosynthetic Photon Flux Density (PPFD) levels across the canopy – ensuring enough light energy for robust growth without causing light stress or burn. Accurate, reliable timers are essential for maintaining the strict photoperiods (e.g., 18 hours light/6 hours dark for veg; 12 hours light/12 hours dark for flower) that govern plant development. Even canopy coverage might be achieved using light movers or careful fixture placement.

Climate Control (HVAC-D): Maintaining stable temperature and relative humidity (RH) within optimal ranges for each growth stage is critical for plant health and quality. This typically requires integrated systems including air conditioning (to counteract heat from lights and equipment), heating (if ambient temperatures drop too low), dehumidifiers (essential during flowering to remove moisture transpired by plants and prevent mold/bud rot), and potentially humidifiers (especially for clones and seedlings which prefer higher RH). Growers often manage climate based on Vapor Pressure Deficit (VPD), a measure combining temperature and humidity that influences plant transpiration rates. Properly sizing these systems to handle the specific heat and moisture loads of the grow space is crucial.

Air Management: Dynamic air movement is vital. Internal oscillating fans ensure air circulates throughout the canopy, preventing stagnant microclimates, promoting gas exchange at leaf surfaces, and strengthening plant stems. A separate ventilation system manages air exchange with the outside (or other building zones), typically involving intake fans drawing in fresh, filtered air and exhaust fans removing warm, humid, CO2-depleted air. Exhaust air is almost always passed through activated carbon filters to neutralize the strong cannabis odors before being vented, ensuring discretion and compliance with regulations. Calculating the appropriate airflow rate (CFM – Cubic Feet per Minute) for the room size and heat load is essential. Furthermore, CO2 supplementation via tanks of compressed CO2 or specialized CO2 burners can significantly boost photosynthesis and growth rates when other factors (light, nutrients, water) are optimized, often targeting levels between 1000-1500 PPM during vegetative and early-to-mid flowering stages. Proper monitoring and safety protocols are essential when supplementing CO2.

Growing Method & Medium: The choice of how to support the plants and deliver nutrients significantly impacts workflow and control:

Hydroponics: This encompasses various techniques (DWC, NFT, drip systems, ebb and flow) where roots are bathed in or periodically exposed to a precisely formulated nutrient solution, using inert media like rockwool, coco coir pith, perlite, vermiculite, or clay pebbles primarily for physical support. Advantages include rapid nutrient uptake, potential for accelerated growth, high water efficiency (in recirculating systems), and granular control over nutrition. However, hydroponic systems often require more technical expertise, offer less buffering capacity against errors (pH or nutrient swings can cause rapid problems), and require diligent system maintenance.

Aeroponics: An advanced form where roots hang in the air within a chamber and are periodically sprayed with a fine mist of nutrient solution. This maximizes root zone oxygenation, potentially leading to very fast growth. However, it’s highly sensitive to equipment malfunction (clogged misters, pump failure) and requires meticulous management.

Soilless Mixes: Using commercially available or custom-blended mixes, often based on peat moss or coco coir amended with perlite, vermiculite, or other components to improve aeration and drainage. Plants are grown in containers (fabric pots, plastic pots) and typically fed via fertigation – watering with pre-mixed nutrient solutions. This method offers a popular balance, providing better aeration and control than traditional soil, while still offering some buffering capacity compared to pure hydroponics. Coco coir, in particular, is valued for its inertness, excellent water retention, and good cation exchange capacity (CEC).

Living Soil (Indoor): Adapting organic, soil-based cultivation for indoor environments. This involves using large containers or beds filled with a carefully crafted soil mix rich in beneficial microorganisms and organic amendments. The focus is on feeding the soil biology, which in turn breaks down nutrients and makes them available to the plant. This method can produce complex terpene profiles but requires different management skills compared to sterile hydroponic/soilless methods, often involving slower growth cycles and more complexity in precisely managing nutrient availability throughout the crop cycle.

Nutrients & Monitoring Tools: Providing the correct nutrition in the proper balance is fundamental:

High-Quality Nutrients: Indoor growers typically rely on nutrient lines specifically designed for cannabis and compatible with their chosen growing medium. These are often multi-part liquid or soluble powder formulas (e.g., Grow A/B, Bloom A/B) allowing growers to adjust nutrient ratios (especially NPK) between vegetative and flowering stages. Base nutrients provide the core macro and micronutrients, while various supplements (Calcium/Magnesium additives, PK boosters for flowering, silica for plant strength, beneficial microbes, enzymes) might be used to optimize specific aspects of growth or plant health. Using reputable brands ensures quality ingredients and accurate formulations.

pH & EC/PPM Meters: These instruments are indispensable for managing nutrient solutions. A pH meter measures acidity/alkalinity; maintaining the correct pH range (typically 5.5-6.5, varying slightly by medium) is crucial because nutrient availability changes drastically outside the optimal zone (risking “nutrient lockout” even if nutrients are present). An EC (Electrical Conductivity) or PPM (Parts Per Million) meter measures the total concentration of dissolved salts in the nutrient solution, indicating its strength. Monitoring EC/PPM helps prevent underfeeding or overfeeding (which can cause nutrient burn). Regular calibration of these meters is essential for accuracy.

Purified Water Source: Water quality is a critical, often overlooked, starting point. Municipal tap water contains variable levels of chlorine, chloramine (harmful to beneficial microbes), minerals (affecting baseline EC/PPM), and potential contaminants. Using filtered water, most commonly water purified via Reverse Osmosis (RO), removes virtually all dissolved solids and chemicals. This provides a clean, consistent starting point (EC ~0.0) allowing the grower complete control over the nutrient profile added to the water. While highly beneficial, RO water is stripped of minerals, so growers using it often need to supplement with Calcium and Magnesium, elements typically present in tap water but essential for plant growth. Less complete options like activated carbon filters can remove chlorine/chloramine but not dissolved solids.

Integrated Pest Management (IPM) Strategy: In a closed indoor environment, prevention is exponentially more effective than treatment. A robust IPM strategy focuses on stopping pests and diseases before they start:

Strict Sanitation: Rigorous cleaning and disinfection of the grow space, tools, and equipment between crop cycles is fundamental. Personnel hygiene protocols, like changing clothes/shoes before entering the grow area, minimize introducing external contaminants.

Filtered Air Intake: Using HEPA or MERV-rated filters on air intakes physically blocks entry of many airborne pests (like spider mites, thrips) and fungal spores.

Quarantine Procedures: All new plants (clones or seedlings from external sources) must be isolated and carefully inspected for a period before being introduced into the main grow population to prevent importing pests or diseases.

Diligent Monitoring: Regular visual inspection of plants (especially leaf undersides) and the use of yellow sticky traps help detect pest presence early when populations are small and easier to manage.

Biological Controls: Proactively releasing beneficial insects (e.g., specific predatory mite species for spider mite control, Stratiolaelaps scimitus (formerly Hypoaspis miles) for fungus gnat larvae in soil/coco) can establish a natural defense mechanism.

Minimal & Targeted Pesticide Use: Chemical pesticides are strongly avoided on consumable flower. If intervention is absolutely necessary, only OMRI-listed or approved biological/organic pesticides (like insecticidal soaps, specific oils, microbial insecticides like Bacillus thuringiensis) should be used cautiously and targetedly, strictly following safety guidelines and pre-harvest intervals.

Monitoring & Automation Equipment: Maintaining optimal conditions 24/7 relies on accurate monitoring and, increasingly, automation:

Sensors: Reliable digital thermometers and hygrometers are essential for tracking air temperature and relative humidity. Sensors may also monitor water temperature, CO2 levels, and nutrient solution pH/EC.

Environmental Controllers: Sophisticated controllers can integrate and automate various systems. They monitor sensor readings and activate/deactivate equipment (lights, AC, heaters, dehumidifiers, humidifiers, CO2 regulators, exhaust fans) based on pre-set parameters. This ensures conditions remain stable day and night, reduces manual labor, minimizes human error, and often includes data logging capabilities for analyzing trends and optimizing conditions over time. Remote monitoring and alerts via smartphone apps are also common features.

Understanding the Entire Indoor THCA Flower Process

The beauty of indoor cultivation lies in its potential for continuous, precisely managed cycles, independent of external seasons. Growers can meticulously guide plants through each life stage, optimizing conditions at every step to coax out the highest levels of quality, potency, and desired characteristics. This controlled journey allows for a level of predictability and refinement often unattainable outdoors, resulting in consistently high-grade THCA flower when executed properly. Here’s a detailed look at the typical stages of indoor THCA flower production:

Strain Selection & Sourcing: It begins with choosing high-quality cannabis genetics known to flourish indoors and express desirable traits like high THCA content, unique terpene profiles, appealing bud structure, and manageable growth habits for the specific setup. Seeds or clones are sourced from reputable breeders or nurseries.

Germination/Cloning: Seeds are germinated under controlled conditions (e.g., paper towel method, starter plugs), or cuttings (clones) are taken from healthy mother plants and rooted in a dedicated propagation area with appropriate humidity and gentle lighting. This ensures a strong start for the young plants.

Vegetative Stage: Once established, the young plants move into the main vegetative growth area. Under 18 to 24 hours of light per day (often using a blue-leaning spectrum light), the focus is on developing a robust root system and a strong, bushy plant structure. Key activities include:

Environmental Control: Maintaining optimal temperature (typically 70-85°F), humidity (40-70% RH), and airflow.

Nutrient Delivery: Providing nitrogen-rich nutrient solutions tailored for vegetative growth, with careful pH and EC monitoring.

Training Techniques: Employing methods like topping, FIMing, Low-Stress Training (LST), Screen of Green (ScrOG), or Sea of Green (SOG) to maximize light exposure to future bud sites and manage plant height/shape.

CO2 Supplementation: Often introduced during this stage to boost growth rates.

Flowering Stage: This crucial phase is initiated by switching the light cycle to exactly 12 hours of uninterrupted darkness followed by 12 hours of light. Again, this photoperiod change signals the plants to start producing THCA flowers (buds). Key adjustments include:

Light Spectrum: Often shifting to a more red-heavy spectrum (if using adjustable LEDs or switching from MH to HPS lamps) to promote flowering. Light intensity is typically maximized.

Strict Dark Period: Ensuring absolute darkness during the 12-hour off-cycle is critical; light leaks can stress plants and hinder flowering.

Environmental Shift: Temperature may be slightly lowered, and relative humidity is significantly reduced (often 40-50% RH) to help prevent mold and encourage resin production.

Nutrient Change: Shifting to bloom-specific nutrient formulas lower in nitrogen and higher in phosphorus (P) and potassium (K).

Monitoring Trichomes: As buds develop, growers use magnification (loupes or microscopes) to monitor the trichome heads (resin glands) for maturity, observing the shift from clear to milky/cloudy and then amber.

Flushing (Optional but Widely Practiced): In the final 1-2 weeks before harvest, many indoor growers using hydroponics or soilless mixes will cease feeding nutrients and provide only pH-adjusted water. This is believed to help the plant utilize or purge residual nutrient salts, potentially leading to a cleaner taste and smoother burn.

Harvesting: The harvest window is determined by trichome inspection, targeting the desired ratio of milky to amber trichomes based on the strain and desired effects profile. Plants are carefully cut down within the controlled environment, handling buds gently to preserve the delicate resin glands.

Trimming: Excess fan leaves and sugar leaves are meticulously removed from the buds. This is typically done either right after harvest (wet trimming) or after the initial drying period (dry trimming). For high-quality indoor THCA flower, hand-trimming is the gold standard, carefully sculpting the buds to enhance visual appeal and preserve trichomes, avoiding the damage often caused by machine trimmers.

Drying: This is a critical stage requiring precise control. Trimmed buds or branches are hung in a dedicated drying room or space that is dark, cool (ideally 60-70°F / 15-21°C), and maintained at a stable relative humidity (around 55-65% RH), with gentle, indirect airflow. The goal is a slow, even drying process over 7-14 days to preserve volatile terpenes and cannabinoids.

Curing: Once the buds reach the desired dryness (smaller stems snap cleanly), they are placed into airtight containers, typically wide-mouth glass jars, for the curing process. Stored in a cool, dark environment, the jars are opened (“burped”) regularly (daily at first, then less often) for several weeks to months. This stabilizes moisture, breaks down chlorophyll and other harsh compounds, and allows the terpenes and cannabinoids to fully mature, resulting in optimal flavor, aroma, smoothness, and shelf life.

Quality Control & Testing: Rigorous checks are performed post-cure. Representative samples from each batch are sent to an accredited third-party laboratory for analysis. Testing confirms THCA potency, ensures Delta-9 THC compliance (<0.3% by dry weight), screens for contaminants (pesticides, heavy metals, microbial life, residual solvents if applicable), and provides a detailed terpene profile. Visual inspection assesses bud structure, density, trichome coverage, color, trim quality, and overall consistency.

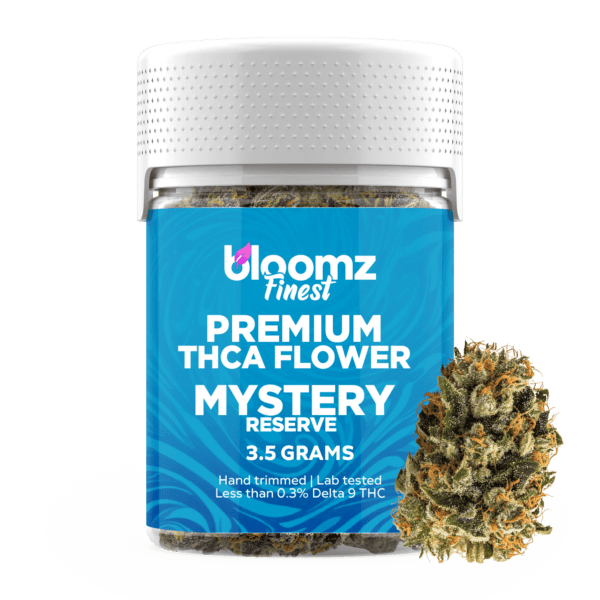

Packaging: The final step involves carefully weighing and placing the finished, tested, and cured indoor THCA flower into appropriate retail packaging designed to protect its quality, meet regulatory standards, and showcase its premium attributes.

Why is Each Step Vital to the Indoor THCA Flower Making Process Anyways?

In the meticulously controlled biosphere of an indoor grow operation, every single step is a load-bearing pillar supporting the final quality of the THCA flower. Unlike outdoor cultivation where nature dictates many terms, indoor growing places the responsibility for every environmental parameter and procedural detail squarely on the cultivator. Precision and consistency are paramount, and neglecting or compromising any phase can create a domino effect, preventing the flower from reaching the peak potential that controlled environments make possible. Success is built on flawless execution from start to finish:

Strain Selection & Sourcing: Crucial because the controlled environment allows growers to push genetics hard. Choosing stable, high-performing strains suited for the specific indoor setup (e.g., height limitations, chosen grow method) maximizes the return on investment in environmental control. Starting with subpar genetics wastes the potential of the controlled environment.

Germination/Cloning: A strong, healthy start in a sterile, controlled propagation environment ensures vigorous seedlings or clones that can quickly adapt and thrive when moved into the main system, minimizing losses and maximizing uniformity – a key goal of indoor cultivation.

Vegetative Stage: This phase builds the “engine” of the plant. Precise control over light, nutrients, and environment allows growers to develop optimal plant structures (strong roots, sturdy stems, ideal canopy shape via training) capable of supporting heavy, high-quality flower production later. Maximizing vegetative health directly translates to yield and quality potential.

Flowering Stage: This is where the magic happens, and absolute control is vital. Strict adherence to the 12/12 light cycle, precise temperature/humidity management to optimize resin production and prevent mold, and tailored bloom nutrients directly influence bud density, THCA synthesis, terpene expression, and overall quality. Any deviation (light leaks, environmental swings) can cause stress, reduce yield, or compromise quality.

Flushing (if practiced): Important in many indoor systems (especially hydro/soilless) to ensure residual nutrients don’t negatively impact the final taste and smoothness. It’s seen as a final refinement step made possible by the controlled feeding regimen.

Harvesting: Nailing the harvest window based on precise trichome inspection is key to capturing the desired potency and terpene profile that the controlled environment helped create. Harvesting too early or too late indoors means failing to capitalize on the optimized growing conditions.

Trimming: Meticulous hand-trimming is vital for achieving the high “bag appeal” expected of premium indoor THCA flower. It preserves the maximum number of trichomes (protected from harsh outdoor elements, they are abundant but delicate) and showcases the bud’s structure, reflecting the care taken during cultivation.

Drying: Absolutely critical. The controlled indoor drying environment allows for the slow, even removal of moisture, which is essential to lock in the terpenes and cannabinoids meticulously developed during flowering. Improper drying (too fast, too slow, wrong conditions) can completely ruin the aroma, flavor, and smoothness of otherwise perfect flower.

Curing: The final polish. Curing in airtight containers allows the chemical profile to stabilize and mature, transforming well-dried indoor buds into a truly premium product with optimal aroma, flavor complexity, and smooth consumption characteristics. Skipping or rushing the cure wastes the potential created upstream.

Quality Control & Testing: Essential for verifying the results of the controlled process. Lab testing confirms the high potency and specific terpene profiles expected from indoor cultivation and ensures the product is free from contaminants – crucial for consumer trust, especially given the contrlled inputs. Consistent QC reinforces brand reputation.

Packaging: The final shield. Protective packaging is vital to maintain the pristine quality achieved indoors, preventing degradation from light, air, and moisture after the product leaves the controlled facility. It ensures the consumer receives the flower in the condition the cultivator intended.

In indoor cultivation, each step is an opportunity to apply precision and control, cumulatively building towards a final product characterized by consistency, potency, and refinement.

How is the Packaging Itself for Indoor THCA Flower Made and Designed?

After the meticulous journey of cultivation, drying, and curing within a controlled indoor environment, the packaging of Indoor THCA flower becomes the final, critical stage in preserving and presenting the product. High-quality indoor flower, often characterized by its vibrant appearance, dense trichome coverage, and potent aroma, requires packaging specifically designed to protect these attributes. The packaging must act as a barrier against environmental elements like UV light, oxygen, and moisture loss or gain, which can rapidly degrade cannabinoids and terpenes. Furthermore, it needs to ensure physical protection for the often delicate buds, comply with all regulatory mandates (including child-resistance and labeling), and effectively communicate the quality and branding associated with premium indoor cultivation.

Biodegradable Jars

Manufactured using sustainable materials like plant-based bioplastics (PLA from corn/sugarcane) or composites incorporating bamboo or wood fibers, these jars are typically formed via injection or compression molding. The design process focuses on creating an effective airtight seal using precisely engineered lids and potentially liners, aiming to preserve freshness. While often naturally opaque or semi-opaque offering some light protection, pigments can be added for branding. The core appeal lies in aligning the premium indoor product with eco-conscious values.

Designed to house indoor THCA flower, these jars provide rigidity to prevent buds from being crushed, showcasing their structure. The seal’s quality is paramount for maintaining the specific moisture content achieved during curing and preventing terpene evaporation or oxidation – crucial for preserving the flower’s potent aroma and effects. While perhaps not offering the hermetic seal of perfectly designed glass or foil, good designs aim for high performance. The surface allows clear labeling, enabling brands to detail strain information, potency, and highlight both the indoor origin and sustainable packaging.

Pros:

Environmentally friendlier option compared to traditional plastics.

Often opaque or semi-opaque, offering light protection.

Rigid structure protects bud integrity.

Appeals to eco-conscious consumers.

Can provide a good seal if well-manufactured.

Cons:

Can be more expensive than standard plastics.

Seal effectiveness and long-term barrier properties may vary.

Biodegradation often requires specific industrial composting.

May not be perceived as premium as glass by all consumers.

Glass Jars

Produced by melting silica sand, soda ash, and limestone at high temperatures, molten glass is shaped into jars via blow or press molding. Lids (metal/plastic) with specialized liners (plastisol, foam, etc.) are engineered to create a tight seal. Design choices include clear glass to showcase the product’s visual appeal (a major plus for indoor THCA flower) or amber/colored glass for enhanced UV protection, alongside variations in thickness and shape for branding and durability.

Glass is favored for indoor THCA flower due to its inert nature, which perfectly preserves the carefully cultivated terpene profile without any chemical interaction. A primary design focus is the seal’s ability to be truly airtight, preventing moisture loss and oxygen ingress, thus maintaining freshness and potency. Clear glass is often chosen specifically to display the high “bag appeal” (vibrant colors, frostiness) typical of premium indoor buds. UV-protective glass offers better long-term preservation if visibility isn’t the top priority. The premium feel and excellent surface for labeling contribute to a high-end product perception.

Pros:

Chemically inert, ensuring perfect preservation of flavor/aroma.

Can provide an excellent, long-lasting airtight seal.

Premium aesthetic allows showcasing of high-quality indoor flower (clear glass).

Offers UV protection options (colored glass).

Provides complete physical protection due to rigidity.

Glass is recyclable.

Cons:

Breakable and heavier than alternatives.

Clear glass offers no UV protection.

Generally, more expensive packaging option.

Seal depends heavily on lid/liner quality and proper closure.

Recommended products

Mylar Bags

These are multi-layer laminated pouches, often combining PET (for printability/strength), aluminum foil (for barrier properties), and PE (for heat sealing). Layers are bonded, and bags are formed with features like zippers, tear notches, and gussets. The aluminum foil layer is key, making the bags opaque and highly resistant to oxygen and moisture transmission. High-quality printing techniques allow for vibrant branding.

Mylar bags are designed to provide excellent protection against light, oxygen, and moisture, preserving the freshness, aroma, and potency of indoor THCA flower. Their opacity ensures complete UV protection. While flexible and offering less crush protection than jars, they are lightweight and efficient. Resealable zippers add convenience, and child-resistant mechanisms are commonly integrated. The large surface area is ideal for branding and displaying detailed information (lab results, strain characteristics) often associated with meticulously grown indoor products.

Pros:

Excellent barrier against light, oxygen, and moisture.

Lightweight and space-saving.

Complete UV protection (opaque).

Often feature convenient resealable zippers.

Large surface area for high-impact branding and info.

Easily incorporate child-resistant features.

Cost-effective solution.

Cons:

Minimal protection against physical crushing.

Zipper seals can be less reliable over time than jar seals.

Can be perceived as less premium than glass.

Difficult to recycle due to mixed materials.

Vacuum Sealed Bags

Made from durable, multi-layer plastic films (e.g., PE/PA) designed for low oxygen permeability, these bags require a vacuum sealer machine to remove air before heat sealing. Some bags have textured surfaces to aid air removal. They are produced via co-extrusion and forming.

The primary design goal is oxygen removal to dramatically slow degradation, making them ideal for preserving the peak freshness and potency of indoor THCA flower, especially for longer-term storage or bulk handling before final retail packaging. While offering excellent preservation, they provide little crush protection and are not typically used for the final consumer-facing retail unit due to lack of shelf appeal and non-resealability.

Pros:

Superior preservation by minimizing oxygen exposure.

Maximizes shelf life significantly.

Effectively contains potent indoor aromas.

Creates very compact storage.

Relatively low bag material cost.

Cons:

Requires a vacuum sealer.

Minimal crush protection; can compress buds.

Not resealable after opening.

Generally, not used for final retail presentation.

Plastic waste considerations.

Plastic Vials/Tubes

Typically, injection molded from resins like polypropylene (PP), polystyrene (PS), or PET. Molten plastic is forced into molds to create the container and lid (often push-and-turn for child resistance). Designs can be clear or opaque, with options for tamper-evident seals.

These offer a rigid structure providing good crush protection for smaller amounts of indoor THCA flower (e.g., grams, pre-rolls). Clear versions allow visibility of the product. PP offers good chemical resistance. Child-resistant closures are standard for compliance. While functional, the seal’s long-term airtightness might be less robust than premium jars or Mylar bags. They represent a practical and often cost-effective choice for smaller units.

Pros:

Good crush protection.

Often include CR and tamper-evident features.

Relatively inexpensive.

Lightweight.

Available in clear or opaque formats.

Suitable for smaller quantities/pre-rolls.

Cons:

Seal effectiveness and long-term airtightness can vary.

May have a less premium perception than glass.

Environmental concerns regarding plastic.

Potential for minor interaction over very long periods (less likely with PP).

For Retailers and Consumers: Ways to Identify Properly Made Indoor THCA Flower

Identifying high-quality Indoor THCA flower involves recognizing the hallmarks of meticulous cultivation within a controlled environment. Because indoor growing allows for such precision, discerning retailers and consumers can often spot superior products by looking for specific visual, aromatic, and tactile cues, alongside verifying data like lab reports. Properly made indoor flower typically exhibits a level of refinement and consistency that reflects the significant investment in technology, expertise, and environmental control required for its production. Knowing what to look for helps ensure you’re getting a product that truly represents the potential of indoor cultivation.

How Retailers Can Identify Properly Made Indoor THCA Flower

Retailers sourcing indoor THCA flower should leverage the potential for consistency and quality control inherent in this cultivation style. Verifying authenticity and quality involves several key checks, such as:

Partnering with Reputable Indoor Cultivators: Work with growers or brands known for their clean, well-managed indoor facilities and consistent, high-quality output. Transparency about growing methods (hydroponic, living soil, etc.), environmental controls, IPM practices, and post-harvest procedures is crucial.

Demanding and Verifying Comprehensive COAs: Always obtain batch-specific Certificates of Analysis from accredited labs. Key points for indoor flower:

Potency: Confirm high THCA levels and Delta-9 compliance. Indoor allows pushing potency potential.

Safety: Check for passing results on pesticides (should be minimal to none in clean indoor grows), heavy metals (especially if using certain hydroponic nutrients), and microbial contaminants (mold can still occur if humidity isn’t controlled). Check for residual solvents if extraction-based products are involved nearby.

Terpene Profile: Look for high concentrations and complexity, reflecting careful cultivation and curing aimed at preserving these volatile compounds.

Conducting Rigorous Sensory Evaluations: Indoor THCA flower often excels in sensory attributes:

Sight (Bag Appeal): Expect dense, well-formed buds, often with vibrant colors (bright greens, purples, oranges), heavy trichome coverage (“frosty” appearance), and meticulous hand-trimming with minimal leaf or stem. Consistency in appearance across buds is a good sign.

Smell (Nose): Aroma should be clean, pungent, and clearly represent the strain’s characteristic terpene profile (e.g., gassy, fruity, citrusy, piney). There should be no hint of mustiness, mildew, chemicals, or nutrient smells.

Touch: Buds should feel dense and sticky due to high resin content, and well-cured (slight spring, not brittle or damp).

Assessing Consistency: High batch-to-batch consistency in appearance, aroma, and lab results is a key indicator of a well-controlled indoor operation. Significant variations might suggest process control issues.

Evaluating Packaging: Ensure the packaging is professional, airtight, compliant, and suitable for preserving premium indoor THCA flower, potentially offering visibility (like a clear jar) to showcase its quality.

How Consumers Can Identify Properly Made Indoor THCA Flower

Consumers seeking the premium experience often associated with indoor THCA flower can look for several indicators of quality at the point of sale and after purchase:

Choose Retailers Known for Quality Indoor Selection: Patronize dispensaries that curate their indoor offerings carefully and whose staff can speak knowledgeably about different brands and cultivation methods.

Research Brands Focusing on Indoor Cultivation: Look for brands that specialize in indoor growing and are transparent about their processes. Online presence, reviews (taken with caution), and brand reputation can provide clues.

Examine Lab Reports (COAs): Don’t hesitate to ask for or look up the COA via QR code. Verify high THCA, low Delta-9 THC, and passing safety tests. Check the terpene profile for insight into potential aroma and effects.

Look for Visual Hallmarks:

Sight: Inspect the flower (if possible through packaging). Look for dense buds, abundant frosty trichomes, vibrant colors, and a very clean, close trim. These are often signs of well-executed indoor cultivation.

Smell: Upon opening, the aroma should be potent, clean, and appealing, matching the expected profile of the strain. Lack of strong aroma or any off-smells are red flags.

Feel (Post-Purchase): Buds should feel dense, sticky, and expertly cured (not too dry, not too wet).

Consider the Price Point: Indoor cultivation involves significant overhead costs (electricity, equipment, facility). Expect high-quality indoor flower to command a higher price than outdoor options. Price often reflects the investment in quality control and consistency.

Check the Packaging: Look for professional, airtight, compliant packaging that protects the flower. Premium indoor brands often use packaging (like glass jars) that reflects the quality inside.

Assess the Overall Experience: Ultimately, high-quality indoor THCA flower should provide a smooth, clean, flavorful experience with effects consistent with its tested potency and terpene profile, often described as feeling potent and refined.

Crafting Indoor THCA Flower Really is an Intricate Process!

The creation of premium Indoor THCA flower stands as a powerful demonstration of human ingenuity applied to horticulture. It’s a process defined by precision, where cultivators become architects of ideal environments, meticulously dialing in light, climate, and nutrition to guide the plant towards its utmost potential. This journey, shielded from the unpredictability of the outdoors, demands constant vigilance, technical expertise, and a significant investment in technology, all orchestrated to achieve unparalleled consistency and quality. The resulting buds, often visually stunning and reliably potent, are a direct reflection of this controlled, science-driven approach, offering a unique expression of cannabis born from a perfectly managed world.

To Buy Indoor THCA Flower Click Here

Recommended products

-

Blazed Exotic THCA Flower

$36.99$79.99 -

THCA Moonrocks – Gold Line

$57.99$89.99 -

Exotic THCA Pre-Rolls Gold Line – 3-Pack/6 Pack

$36.99$69.99