Ever gaze upon a truly magnificent bud of AAA Exotic THCA Flower, marveling at its crystalline coat, intricate structure, and captivating aroma, and wonder just how it came to be? It’s far more than just putting a seed in the ground and waiting. Crafting cannabis of this caliber is a symphony of science, art, and meticulous dedication, a journey from a humble seed to the final, premium product that reaches your hands.

It’s a process demanding expertise at every turn, where cutting corners isn’t an option if true top-tier quality is the goal. Ready to peek behind the curtain and uncover the secrets behind producing this exceptional flower? Let’s embark on the fascinating voyage that transforms potential into perfection.

TO BUY AAA EXOTIC THCA FLOWER CLICK HERE

A Quick Insight into What AAA Exotic THCA Flower is

Simply put, AAA Exotic THCA flower starts with the “AAA” rating, a commonly used, albeit informal, grading system within the cannabis community signifying superior quality. Think of it as the A-list of cannabis buds – visually stunning, aromatically captivating, and packed with desirable compounds.

The “Exotic” descriptor points to unique, often rare genetics, resulting in distinct flavors, aromas, and appearances that you won’t find in more common strains. These cultivars are often the result of meticulous breeding programs aimed at pushing the boundaries of potency and sensory experience, offering something truly novel for the discerning user.

The main player here is tetrahydrocannabinolic acid (THCA), the non-intoxicating cannabinoid is the natural precursor to the well-known Delta-9-Tetrahydrocannabinol (THC). In its raw form within the flower, it exists as THCA. It’s only when heat is applied (a process called “decarboxylation”) that the “A” (acid part) drops off, converting THCA into the moderate potency of THC.

Essentially, AAA Exotic THCA flower represents the height of cannabis cultivation in the hemp-derived market, focusing on genetics that yield high levels of THCA alongside unique terpene profiles and striking overall appeal. It’s cultivated, harvested, and cured with exceptional care to preserve these delicate compounds and ensure maximum quality. You see, this isn’t your average flower; it’s a premium product sought after for its intensity, unique characteristics, and the provided elevated experience.

What is Initially Needed to Make AAA Exotic THCA Flower?

Prior to the first sprout breaks the surface, creating AAA Exotic THCA flower necessitates a carefully curated collection of resources and expertise. It’s about establishing the ideal foundation, ensuring every element is primed for nurturing elite cannabis genetics to their fullest expression. Think of it as gathering the finest ingredients and tools before a master chef begins crafting a Michelin-star dish. Success hinges on having the right components from the very beginning. Below is a breakdown of the essential initial requirements:

Elite Genetics: Again, this is paramount. It starts with selecting specific, often rare or highly sought-after “exotic” strains known for their unique terpene profiles, high THCA production potential, desirable bud structure, vibrant colors, and exceptional trichome density. Sourcing stable, proven genetics from reputable breeders or maintaining a library of elite mother plants is crucial.

Optimized Growing Medium: The choice of medium significantly impacts nutrient delivery and root health. Options include:

Living Soil: Complex ecosystems rich in beneficial microbes that break down organic matter, feeding the plant naturally. Requires careful management but can yield complex flavors.

Coco Coir: An inert medium made from coconut husks, offering excellent aeration and drainage. Allows for precise nutrient control via fertigation.

Hydroponics/Aeroponics: Soil-less systems (like Deep Water Culture, Nutrient Film Technique, or Aeroponics) that deliver nutrient solutions directly to the roots. Offers rapid growth and high control but demands technical expertise. For AAA quality, the system must be impeccably maintained.

Controlled Environment Agriculture (CEA) Setup: Maintaining precise environmental conditions is non-negotiable for AAA quality. This involves:

Lighting: High-intensity, spectrum-specific lighting like full-spectrum LEDs or potentially optimized HPS (High-Pressure Sodium) lamps, tailored to different growth stages (vegetative vs. flowering) to maximize photosynthesis and cannabinoid/terpene development. Light cycles must be strictly controlled.

Temperature & Humidity Control: HVAC systems capable of maintaining specific temperature ranges (e.g., slightly warmer in veg, slightly cooler in late flower) and relative humidity levels (e.g., higher in veg, lower in THCA flower to prevent mold and optimize resin production). Precise control day and night is key.

Air Circulation & Exchange: Ample airflow using oscillating fans prevents stagnant air pockets, strengthens stems, and helps manage humidity. Filtered air exchange (intake/exhaust) with CO2 supplementation capabilities ensures fresh air and optimal CO2 levels (often elevated during peak growth phases) for photosynthesis.

Tailored Nutrient Regimen: Supplying the precise balance of macronutrients (Nitrogen, Phosphorus, Potassium – NPK) and micronutrients (Calcium, Magnesium, Sulfur, Iron, etc.) is vital. This involves:

High-quality, cannabis-specific nutrient lines.

Carefully planned feeding schedules adjusted for different growth stages (e.g., higher N in veg, higher P and K in flower).

Regular monitoring and adjustment of nutrient solution pH and EC (Electrical Conductivity)/PPM (Parts Per Million).

Pure Water Source: Water quality is critical. Using reverse osmosis (RO) filtered water is standard practice for AAA cultivation, as it removes impurities and allows for complete control over the mineral/nutrient content delivered to the plants. Water pH must be consistently adjusted to the optimal range for nutrient uptake (typically 5.5-6.5, depending on the medium).

Experienced Cultivation Team: Growing AAA Exotic THCA flower isn’t automated. It requires growers with deep knowledge, keen observational skills, and meticulous attention to detail to interpret plant needs, troubleshoot issues, and implement advanced cultivation techniques (like specific training or pruning methods) effectively.

Integrated Pest Management (IPM) Strategy: Proactive and preferably organic/biological pest and disease management is essential. This means regular scouting, maintaining extreme cleanliness, using beneficial insects, and employing OMRI-listed or natural pesticides/fungicides only when absolutely necessary and well before harvest to avoid contamination. Preventing problems is far better than treating them.

Dedicated, Secure Facility: A clean, organized, and secure grow facility designed for efficient workflow and contamination control is necessary. This includes separate areas for different growth stages, drying, curing, and trimming, along with strict hygiene protocols for personnel.

Understanding the Entire AAA Exotic THCA Flower Process

Transforming those initial requirements into stunning AAA Exotic THCA flower involves a sequential, multi-stage process where precision and patience are paramount. Each phase builds upon the last, contributing unique characteristics to the final product. Rushing or neglecting any single step can compromise the potential locked within those elite genetics. It is a meticulous journey from propagation to the perfectly cured bud. Here are the essential steps in order:

Strain Selection & Genetic Sourcing: As mentioned, it begins by choosing the right cultivar known for AAA Exotic traits – unique appearance, potent THCA levels, complex aroma, and specific effects. This involves acquiring seeds or clones from trusted sources.

Germination/Cloning: Seeds are sprouted using methods like the paper towel method or direct sowing, or cuttings (clones) are taken from a healthy mother plant and rooted in plugs or cubes. This establishes the young plants.

Vegetative Stage: Once rooted, seedlings or clones enter the vegetative phase. Under 18-24 hours of light per day, the focus is on developing a strong root system and robust plant structure (stems, branches, leaves). Techniques like topping, FIMing (F*** I Missed), Low-Stress Training (LST), or Screen of Green (ScrOG) may be employed to encourage bushy growth and maximize future bud sites. Nutrient formulas are nitrogen-rich during this stage. Duration varies but typically lasts several weeks

Flowering Stage: This critical phase is initiated by switching the light cycle to 12 hours of darkness and 12 hours of light. The plant shifts its energy from vegetative growth to producing THCA flowers (buds). Nutrient solutions are adjusted, reducing nitrogen and increasing phosphorus and potassium (PK) to support bud development and resin production. Environmental parameters like humidity are often lowered. This stage lasts anywhere from 8 to 12+ weeks, depending heavily on the specific strain’s genetics. Monitoring trichome development (the tiny resin glands containing THCA) is crucial for determining peak ripeness.

Flushing (Optional but Common): In the final 1-2 weeks before harvest, many cultivators flush the plants by feeding them only pH-balanced water. The theory is to remove residual nutrient salts from the growing medium and plant tissues, potentially leading to a smoother, cleaner final product. The necessity and effectiveness of flushing are debated, but it remains a common practice, especially in hydroponic and coco grows.

Harvesting: Timing is everything. Growers harvest when the trichomes have reached their peak maturity, typically indicated by a transition from clear to mostly milky/cloudy, with some amber trichomes appearing (the exact ratio depends on desired effects and strain). Harvesting involves carefully cutting down the entire plant or individual branches. This is often done in a controlled environment to minimize contamination.

Trimming: Immediately after cutting (wet trimming) or after initial drying (dry trimming), excess fan leaves and sugar leaves (smaller leaves growing out of the buds) are meticulously removed. For AAA Exotic flower, hand-trimming is the standard. While time-consuming, it preserves the integrity of the trichomes and the bud’s structure far better than machine trimming, resulting in superior appearance and quality.

Drying: This is a crucial, slow process. Trimmed branches or individual buds are hung in a dark, climate-controlled room, typically maintained at around 60°F (15.5°C) and 60% relative humidity, with gentle air circulation. The goal is a slow, even dry over 7-14+ days. Rushing the drying process (e.g., using heat) severely degrades terpenes and cannabinoids, ruining potential quality. Buds are dry enough when smaller stems snap rather than fold.

Curing: Once dried, the buds are placed into airtight containers (often glass jars) for the curing process. This is where the magic happens for developing the flower’s final aroma, flavor, and smoothness. Containers are stored in a cool, dark place and opened (“burped”) regularly (daily at first, then less frequently) for several weeks to months. Burping releases excess moisture and allows for gas exchange, facilitating enzymatic processes that break down chlorophyll and sugars while preserving terpenes and cannabinoids. A proper cure differentiates good flower from truly exceptional AAA THCA flower.

Quality Control & Laboratory Testing: Before packaging, representative samples from the cured batch are sent to an independent, accredited laboratory. Testing verifies THCA potency (and ensures Delta-9 THC remains below the legal limit, typically 0.3%), screens for harmful contaminants (pesticides, heavy metals, molds, mycotoxins, bacteria), and often includes a terpene profile analysis. Rigorous visual inspection and grading also occur at this stage.

Grading: Based on the lab results and a thorough assessment of physical characteristics – bud density, trichome coverage, color, structure, trim quality, nose (aroma intensity and complexity), and overall bag appeal – the flower is graded. Only the best batches meeting stringent criteria earn the “AAA Exotic” designation.

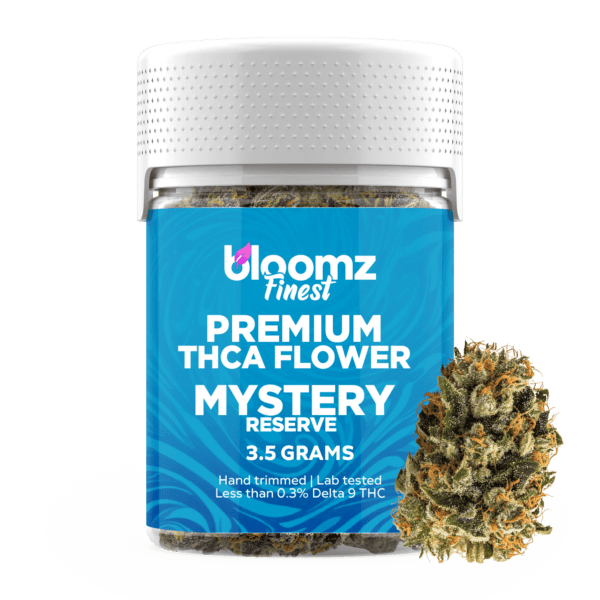

Packaging: The final step involves carefully packaging the graded, tested, and cured flower into appropriate containers designed to protect its quality, comply with regulations (child-resistance, labeling), and showcase its premium nature. This leads directly into preparing the THCA product for sale.

Why is Each Step Vital to the AAA Exotic THCA Flower Making Process Anyways?

Understanding the how is important but grasping the why reveals the true artistry and necessity behind each phase in creating AAA Exotic THCA flower. Skipping, rushing, or poorly executing any single step creates a weak link in the chain, inevitably diminishing the final quality and preventing the flower from reaching its maximum genetic potential. It’s a cumulative process where excellence compounds. Let’s now explore the vital role of each stage:

Strain Selection & Sourcing: This sets the absolute ceiling for potential. You cannot produce exotic AAA traits (unique terpenes, high THCA, specific bud structure) if the genetics don’t possess them. Starting with mediocre genetics guarantees a mediocre outcome, regardless of grower skill. It’s the blueprint for the final product.

Germination/Cloning: A successful start ensures healthy, vigorous plants capable of handling the stresses of growth and training. Poor germination or weak clones lead to stunted growth, lower yields, and increased susceptibility to problems later on. It’s about building a strong foundation.

Vegetative Stage: This phase builds the plant’s “factory.” A well-developed root system and strong canopy structure created through proper nutrition, lighting, and training techniques are essential for supporting massive THCA flower production later. A weak vegetative plant simply cannot yield dense, large, high-quality buds.

Flowering Stage: This is where the prize develops. Precise environmental control (light cycle, temperature, humidity) and tailored nutrient delivery directly influence bud density, size, THCA synthesis, and terpene production. Mistakes here (light leaks, improper nutrients, poor climate control) can lead to stressed plants, low potency, poor flavor, or even hermaphroditism.

Flushing (if practiced): Its proponents believe this step is vital for ensuring a clean, smooth experience by removing any residual salts that could affect taste or burn quality. While debated, its careful implementation is aimed at refining the final palate.

Harvesting: Harvesting too early means underdeveloped trichomes, lower potency, and less complex terpene profiles. Harvesting too late can lead to THCA degradation into other cannabinoids and potentially sedative effects, altering the desired experience. Nailing the harvest window based on trichome inspection is critical for capturing the strain’s peak potential.

Trimming: Meticulous hand-trimming is vital for AAA aesthetics and quality. It preserves the delicate trichomes (where THCA and terpenes reside) that machine trimmers often damage or shake off. A clean trim also enhances visual appeal (“bag appeal”) and prevents harshness caused by excess leaf material. It respects the flower.

Drying: Slow, controlled drying is non-negotiable. Rushing this evaporates volatile terpenes (destroying aroma and flavor) and can trap chlorophyll (leading to a harsh, grassy taste). Improper drying also sets the stage for mold during curing. This step preserves the compounds developed during flowering.

Curing: This is arguably one of the most critical steps differentiating top-shelf from average THCA flower. Curing homogenizes moisture, breaks down harsh compounds like chlorophyll and sugars, and allows terpenes to fully mature and develop complex bouquets. A proper cure results in a smoother experience, enhanced flavor, and longer shelf life. Uncured or poorly cured flower is often harsh, smells grassy, and burns unevenly. It’s the final refinement stage.

Quality Control & Testing: This is vital for consumer safety and product verification. Lab testing confirms potency (ensuring it meets THCA expectations and legal Delta-9 limits) and guarantees freedom from harmful contaminants. It provides transparency and builds trust. Without testing, quality claims are unsubstantiated.

Grading: This step ensures consistency and helps manage expectations. The AAA Exotic grade signifies that the flower has met the highest standards across multiple metrics. It differentiates the truly exceptional batches produced through meticulous execution of all previous steps.

Packaging: Proper packaging is crucial for preserving the quality achieved through the preceding steps. It protects the THCA flower from physical damage, light degradation, moisture loss or gain, and oxygen exposure, all of which can rapidly degrade cannabinoids and terpenes. It’s the final shield protecting the investment in quality.

In essence, each step is a checkpoint for quality. Success requires consistent excellence throughout the entire journey, from the initial genetic selection right through to the final cure and packaging.

How is the Packaging Itself for AAA Exotic THCA Flower Made and Designed?

The journey of AAA Exotic THCA Flower doesn’t end when the bud is perfectly cured and tested; the final presentation and preservation method—the packaging—is a critical component demanding its own careful consideration. Packaging for premium flower serves multiple purposes: protecting the delicate trichomes and overall bud integrity, preserving the precise moisture content achieved during curing, shielding the cannabinoids and terpenes from degradation by light and air, ensuring regulatory compliance (like child-resistance and proper labeling), and conveying the brand’s quality and aesthetic. The materials chosen and the design of the container are engineered to maintain that hard-won AAA quality from the facility to the end user.

Biodegradable Jars

These eco-conscious containers are typically manufactured using plant-based bioplastics or composite materials. Common sources include polylactic acid (PLA), derived from corn starch or sugarcane, or materials incorporating bamboo fibers, wood pulp, or other sustainable resources. The manufacturing process often involves injection molding or compression molding, where the raw bioplastic pellets or material mixture are heated and formed into the desired jar shape and accompanying lid. Design considerations focus heavily on creating an effective seal to maintain freshness, often incorporating liners or specific closure mechanisms. The aesthetic often leans towards natural or earthy tones, reflecting the sustainable materials, though pigments can be added for branding. Some designs might incorporate features to minimize light exposure, although opacity is inherent in many of these materials.

The primary design goal for housing AAA THCA Flower is preservation coupled with sustainability. These jars are engineered to be rigid enough to prevent buds from being crushed. The seal is paramount; designers focus on lid types (often screw-on) and potential inner seals (like pressure seals or foam liners) that create an airtight environment, crucial for preventing moisture loss and oxygen ingress which degrade THCA and terpenes. While not inherently UV-blocking like some glass, the opacity of many biodegradable materials offers decent light protection. The surface allows for labeling or printing, enabling brands to communicate product information and reinforce their eco-friendly image. The material itself is chosen to be non-reactive, ensuring it doesn’t impart any unwanted flavors or leach harmful substances into the flower.

Pros:

Environmentally friendly, reduces plastic waste.

Often opaque, offering some light protection.

Rigid structure protects buds from crushing.

Appeals to eco-conscious consumers and brands.

Can often achieve good airtight seals.

Cons:

Can be more expensive than traditional plastics.

Seal effectiveness can vary depending on design and material quality.

May not offer the same level of long-term inertness or UV protection as glass.

Biodegradability may require specific composting conditions that’re not always available to consumers.

Glass Jars

Glass jars, a classic choice for premium THCA flower, are made primarily from silica sand (silicon dioxide), soda ash (sodium carbonate), and limestone (calcium carbonate). These raw materials are melted together at extremely high temperatures (around 1500°C or 2700°F) in a furnace. The molten glass is then formed into jars using methods like blow molding (injecting air into a gob of molten glass inside a mold) or press molding (pressing the molten glass into a mold). Lids are manufactured separately, often from metal or plastic, and designed with liners (like plastisol or foam) to create an airtight seal when screwed or clamped down (e.g., bail-top jars). Design aspects include choosing glass clarity (clear for visibility, amber/cobalt/opaque for UV protection) and thickness for durability.

Glass is favored for its inertness, meaning it won’t react with the flower or impart any flavors, preserving the original terpene profile. The design focuses heavily on the seal – precision-made threads for screw tops or robust clamping mechanisms for bail tops are critical for maintaining airtightness and the ideal humidity level within. Clear glass is often chosen to showcase the visual appeal of AAA flower, but UV-protective glass (amber or coated) is superior for long-term preservation by blocking degrading light wavelengths. The smooth, rigid surface is ideal for premium label application or even direct printing/etching, enhancing the perceived value. Its impermeability to oxygen makes it excellent for preventing oxidation when properly sealed.

Pros:

Excellent inertness, preserving flavor and aroma perfectly.

Can provide a superior airtight seal if well-designed.

Offers premium aesthetic and feel.

Glass itself is recyclable.

Allows for clear visibility of the product (if clear glass is used).

Offers UV protection options (amber, coated, opaque glass).

Rigid structure fully protects buds.

Cons:

Breakable and heavier than other options.

Clear glass offers no UV protection unless treated or colored.

Can be more expensive than bags or plastic options.

Requires effective lid liners for a true airtight seal.

Mylar Bags

Mylar bags, technically often made from BoPET (biaxially-oriented polyethylene terephthalate) laminated with other materials, are constructed through a multi-layering process. A typical structure involves an outer layer of PET for strength, printability, and puncture resistance; a middle layer of aluminum foil providing excellent barrier properties against light, oxygen, and moisture; and an inner layer of food-grade polyethylene (PE) or similar sealant film that allows the bag to be heat-sealed. These layers are laminated together using adhesives. The bags are then formed, often incorporating features like resealable zipper closures, tear notches for easy opening, gusseted bottoms for stand-up capability, and potentially hang holes. Printing (often high-quality rotogravure or digital) is done on the outer layer before lamination or construction.

The design of Mylar bags prioritizes barrier properties and convenience for packaging AAA Exotic flower. The aluminum foil layer is key, making the bags opaque (blocking light completely) and highly resistant to oxygen and moisture transfer, thus preserving freshness, potency, and aroma. The flexibility of the bag material allows it to conform somewhat to the product, though it offers less crush protection than rigid containers. Zippers provide resealability for consumer convenience, while heat sealing ensures tamper evidence and initial freshness. They are lightweight and space-efficient for storage and transport. Many jurisdictions mandate child-resistant closures on Mylar bags used for cannabis, requiring specific zipper mechanisms (e.g., push-and-pinch). Extensive surface area allows for vibrant branding and required compliance information.

Pros:

Excellent barrier properties (light, oxygen, moisture)

Lightweight and space-efficient

Opaque, providing complete UV protection.

Often includes resealable zippers and tear notches.

Large surface area for branding and information.

Can incorporate child-resistant features.

Generally cost-effective compared to jars.

Cons:

Offers minimal protection against crushing or physical damage to buds.

Zipper seal effectiveness can degrade with use.

Less premium feel compared to glass jars.

Environmental concerns regarding multi-material plastic/foil construction (difficult to recycle).

Recommended products

Vacuum Sealed Bags

Vacuum seal bags are typically made from multi-layer plastic films engineered for strength, puncture resistance, and low oxygen permeability, often using combinations like polyethylene (PE) and nylon (polyamide, PA). One side might be embossed or textured to create air channels, allowing a vacuum sealer machine to efficiently remove air from the bag before sealing. The bags are manufactured through co-extrusion processes, where multiple layers of plastic resin are extruded simultaneously to form a single film with combined properties. They are usually supplied as pre-made bags sealed on three sides or as rolls that can be cut to size.

The core design principle is the removal of oxygen. By using a vacuum sealer machine, nearly all air is evacuated from the bag before it’s heat-sealed shut. This drastically slows down oxidative degradation of cannabinoids and terpenes, preserving freshness and potency for extended periods. These bags are primarily designed for bulk storage or long-term preservation rather than immediate retail presentation, although some brands might use them for specific AAA Exotic THCA flower products. The tight vacuum seal also makes the package very compact and helps lock in aromas. While offering some protection due to the tight fit, they don’t inherently prevent crushing if mishandled.

Pros:

Excellent preservation by removing oxygen, slowing degradation significantly.

Maximizes shelf life, especially for long-term storage.

Locks in aromas effectively until it is opened.

Creates a very compact package

Relatively inexpensive bag material.

Cons:

Requires a vacuum sealer machine.

Offers little crush protection; can compress buds if vacuum is too strong.

Not typically resealable after opening (requires cutting).

Generally, it is not used for final retail presentation due to appearance.

Potential environmental concerns with plastic waste.

Plastic Vials/Tubes

These containers are commonly manufactured using injection molding, a process where molten plastic resin (often polypropylene – PP, known for its good chemical resistance and rigidity, or sometimes polystyrene – PS or polyethylene – PET) is injected under high pressure into a precision-machined mold cavity. Once the plastic cools and solidifies, the mold opens, and the vial or tube is ejected. Lids, often push-and-turn or snap-on types designed for child resistance, are typically molded separately using similar processes. Design features can include opaque or clear plastic, tamper-evident seals (like shrink bands or breakable rings), and smooth surfaces suitable for label application.

Plastic vials are typically designed to hold smaller quantities of AAA Exotic flower, like single grams or pre-rolls. Their rigid structure provides good protection against crushing. Polypropylene, being relatively inert, is often chosen to minimize interaction with the flower. The design often incorporates child-resistant closures to meet regulatory requirements. While they can offer a decent seal, the long-term airtightness might not match high-quality glass jars or Mylar bags, depending on the lid design and tolerances. Clarity permits product viewing, while opacity offers light protection. They represent a functional and often cost-effective solution, particularly for smaller denominations or sample sizes.

Pros:

Good crush protection due to rigid structure.

Often incorporates child-resistant and tamper-evident features.

Relatively inexpensive to produce.

Lightweight compared to glass.

Can be made clear for visibility or opaque for light protection.

Suitable for smaller quantities and pre-rolls.

Cons:

Seal effectiveness and long-term airtightness can vary.

Less premium perception compared to glass.

Potential environmental concerns with plastic waste (though PP is recyclable).

Plastic materials might (though less likely with PP) potentially interact with terpenes over very long periods compared to glass.

Restricted to how much you can have in them.

For Retailers and Consumers: Ways to Identify Properly Made AAA Exotic THCA Flower

In a market brimming with options, distinguishing truly exceptional AAA Exotic THCA flower from lower-grade products is crucial for both retailers seeking to build a reputation for quality and consumers aiming for a premium experience. Proper identification relies on a combination of sensory evaluation, scrutiny of data, and understanding the hallmarks of meticulous cultivation and post-harvest processing. It’s about looking beyond flashy marketing and assessing the tangible characteristics that signify genuine top-tier quality, ensuring the product lives up to its “AAA Exotic” designation.

How Retailers Can Identify Properly Made AAA Exotic THCA Flower

Retailers act as gatekeepers of quality, and their ability to discern properly produced AAA Exotic THCA flower is vital for customer satisfaction and business integrity. Beyond simply trusting supplier claims, savvy retailers employ a multi-faceted approach to verification, such as:

Verifying the Source: Establish relationships with reputable cultivators or distributors known for their consistency, transparency, and high cultivation standards. Visiting facilities (if possible) or having in-depth conversations about their growing, drying, curing, and testing protocols can provide valuable insights. Look for partners who openly share information and prioritize quality over quantity.

Demanding Comprehensive Lab Reports (COAs): Always obtain and scrutinize Certificates of Analysis (COAs) for every batch. Ensure the COA is recent, from an accredited third-party lab (ISO 17025 certified), and includes a full panel:

Potency: Verify high THCA levels consistent with exotic strains and confirm Delta-9 THC is below the legal limit (0.3% by dry weight).

Contaminants: Check for passing results on pesticides, heavy metals, microbials (mold, yeast, bacteria), and mycotoxins. Any failures are immediate red flags.

Terpene Profile: Analyze the dominant terpenes. Does the profile match the expected aroma and characteristics of the claimed strain? High total terpene percentages often correlate with richer aroma and flavor.

Rigorous Sensory Evaluation: Use sight, smell, and touch:

Sight: Look for densely coated trichomes (frosty appearance), well-defined THCA bud structure (dense, not airy or overly leafy), vibrant colors (greens, purples, oranges – not dull brown or yellow), and meticulous hand-trimming (minimal stems and leaves). Inspect closely for any signs of mold, mildew, pests, or contaminants.

Smell (Nose): Open a sample container. The aroma should be pungent, complex, and immediately recognizable as high-quality cannabis, aligning with the strain’s expected terpene profile (e.g., fruity, gassy, earthy, floral). Avoid flower that smells like hay, grass, ammonia, chemicals, or dampness – these indicate improper drying, curing, or contamination.

Touch: Gently squeeze a bud. It should feel slightly sticky due to resin, dense, and have a slight spring-back. It shouldn’t be overly dry and crumble instantly, nor should it feel wet or spongy. Check stem snap – smaller stems should snap cleanly.

Assessing Consistency: Evaluate consistency across different buds within a sample and, ideally, across different batches from the same supplier over time. True AAA quality should be consistent.

Inspecting the Packaging: Ensure the final packaging is professional, compliant with local regulations (child-resistance, labeling), properly sealed, and protects the flower from light and air. Poor packaging can indicate a lack of attention to detail throughout the process.

How Consumers Can Identify Properly Made AAA Exotic THCA Flower

Consumers seeking the best possible experience also need to be discerning. While they may not have direct access to growers, several indicators can help identify genuine AAA Exotic THCA Flower quality at the point of purchase:

Choose Reputable Retailers: Purchase from licensed dispensaries or retailers known for their quality control, knowledgeable staff, and transparency. Retailers who curate their selection carefully are more likely to stock genuine premium products.

Research Brand Reputation: Look into the brands offering the flower. Are they known for quality and consistency? Do they provide information about their cultivation practices? Online reviews and forums can sometimes offer insights, but approach them critically.

Ask for Lab Reports (COAs): Don’t hesitate to ask the retailer (budtender) if you can see the COA for the specific batch you’re considering. Many reputable brands include QR codes on packaging linking directly to lab results. Look for high THCA, compliant Delta-9 THC, passing safety tests, and ideally, a terpene profile.

Use Your Senses (Where Possible):

Sight: Examine the flower closely (if visible through packaging or if display jars are available). Look for the hallmarks: abundant frosty trichomes, vibrant colors, tight bud structure, and a clean, hand-trimmed appearance. Avoid flower that looks dull, leafy, overly stemmy, or shows signs of mold.

Smell: If you can smell the product before buying (e.g., display jars, though less common with pre-packaged goods), it should have a strong, inviting, and complex aroma specific to cannabis terpenes. Upon opening your purchase at home, this aroma should be immediately apparent and pleasant. A lack of smell or off-putting odors are negative signs.

Feel (Post-Purchase): Once you can handle the THC flower, check for stickiness (resin), density, and proper moisture level (slight spring, not crumbly or damp).

Consider the Price Point: AAA Exotic THCA Flower involves significant investment in genetics, time, and expertise. Expect it to command a premium price. While price isn’t the only indicator, be skeptical of products marketed as “AAA Exotic” at unusually low prices, as quality compromises may have been made.

Evaluate Packaging: Look for professional, airtight, and compliant packaging that protects the flower and provides necessary information (strain, potency, warnings, batch number, QR code for COA). Tamper-evident seals provide assurance.

Trust Your Experience: Ultimately, the effects and overall experience (smoothness, flavor, desired feelings like relaxation or euphoria) after consumption are key indicators. High-quality flower should provide a clean, flavorful experience consistent with its profile.

Crafting Premium AAA Exotic THCA Flower Really is an Intricate Process!

The journey culminating in AAA Exotic THCA flower transcends simple farming; it embodies a profound dedication to excellence at every conceivable stage. It’s a testament to the harmonious blend of horticultural science, technological precision, and the irreplaceable touch of human artistry. From the foundational decision of selecting world-class genetics to the patient, intuitive finesse required during the final weeks of curing, each action is deliberate, each detail magnified.

This intricate dance requires not just knowledge, but passion—a relentless pursuit of unlocking the absolute peak expression of the cannabis plant. The resulting flower, with its dazzling appearance, complex aromatics, and remarkable quality, stands as a monument to this unwavering commitment, offering an experience far removed from the ordinary and truly celebrating the pinnacle of cannabis cultivation.