Have you ever held a bud of truly Exotic THCA flower, noted its unique structure, inhaled its distinct and powerful aroma, and felt a spark of curiosity about its origins? Its journey is far more intricate than simply planting a seed and adding water. Producing cannabis with that special “exotic” quality—marked by rare genetics, striking appearances, and complex terpene profiles—is an elaborate dance between nature and nurture, guided by expert hands. It’s a path demanding unwavering attention to detail, where shortcuts simply don’t lead to the desired destination. So then, let’s cover the fascinating world behind the creation of Exotic THCA flower, shall we.

To Buy Exotic THCA Flower Click Here

Recommended products

-

THCA Flower – Platinum Line

$49.99$79.99 -

Exotic THCA Smalls

$179.99$329.99 -

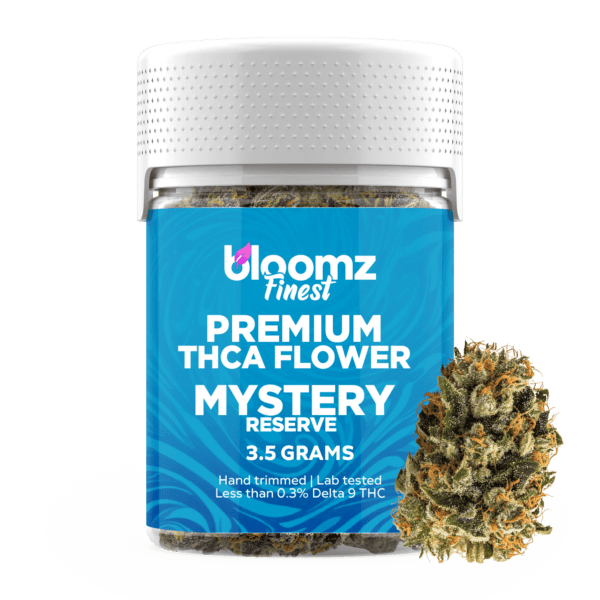

THCA Flower – Mystery Reserve

$41.99$79.99 -

THCA Flower – Exotics – Gold Line

$37.99$69.99

A Quick Insight into What Exotic THCA Flower is

Pertaining to the coveted “Exotic” label given to THCA flower, this mainly surrounds the genetics and the resulting unique characteristics that set it apart from more common or classic strains. Exotic flower typically stems from innovative breeding projects, cross-breeding rare or landrace strains, or selecting unusual phenotypes that express distinctive traits. These traits manifest as uncommon terpene profiles leading to unique aromas and flavors, striking visual appeal, and potentially novel combinations of effects. It’s the “OMG” factor – something that immediately signals this isn’t your standard fare. These cultivars are often less widely available, adding to their allure and desirability among connoisseurs seeking novelty and distinction.

This category specifically focuses on flower rich in tetrahydrocannabinolic acid (THCA) – the also legal and non-intoxicating precursor cannabinoid that converts to intoxicating Delta-9 THC when heated (decarboxylated). The combination of rare genetics and high THCA potential makes exotic THCA flower a highly sought-after product for those seeking both a unique sensory journey and substantial effects, all within the legal hemp framework.

Therefore, Exotic THCA Flower represents a fusion of genetic artistry and targeted cultivation aimed at producing hemp flower with standout characteristics and significant potency potential. While cultivation methods can vary, the emphasis is on nurturing the plant to fully express its unique genetic blueprint. These aren’t mass-market strains; they are often the result of passionate breeders and cultivators pushing the boundaries of what’s possible in cannabis, offering users a chance to experience truly different and memorable profiles. Recognizing this focus is imperative to appreciating what makes this category amazing.

What is Initially Needed to Make Exotic THCA Flower?

Laying the groundwork for cultivating exceptional Exotic THCA flower requires assembling a specific set of high-quality inputs and establishing precisely controlled conditions from the outset. It’s about creating the perfect environment and providing the ideal resources to allow unique and often demanding genetics to flourish and express their full, captivating potential. Basically, success is deeply rooted in getting these initial components exactly right:

Elite & Unique Genetics: Again, this is the cornerstone. The process begins with sourcing rare, sought-after “exotic” cannabis strains. These genetics are chosen for specific desirable traits: distinctive terpene profiles (leading to unique aromas and flavors), high potential for THCA production, unusual coloration (purples, deep greens, vibrant pistils), interesting bud structures, and copious trichome coverage. Acquiring authentic, stable genetics from reputable breeders or meticulously maintaining a genetic library of mother plants is absolutely critical.

Optimized Growing Medium: The substrate chosen profoundly impacts root development and nutrient availability. Common choices for high-quality cultivation include:

Living Soil: A complex, microbe-rich medium that breaks down organic amendments to feed the plant naturally, often contributing to nuanced flavor profiles. Requires careful balancing and maintenance.

Coco Coir: Derived from coconut husks, this inert medium provides excellent drainage and aeration, allowing growers precise control over nutrient delivery through fertigation.

Hydroponic Systems: Methods like Deep Water Culture (DWC), Nutrient Film Technique (NFT), or Aeroponics deliver nutrient solutions directly to the roots without soil. These can promote faster growth and allow fine-tuned nutrient management but demand significant technical expertise and system cleanliness.

Precision Environmental Controls: Maintaining stable and optimal environmental conditions is non-negotiable for coaxing the best out of exotic genetics. Key elements include:

High-Quality Lighting: Utilizing powerful, spectrum-appropriate lighting systems such as full-spectrum LEDs or tailored HPS lamps is crucial. Light intensity and spectrum are adjusted for vegetative and flowering stages to drive photosynthesis and optimize cannabinoid/terpene synthesis. Strict adherence to light cycles (e.g., 18/6 for veg, 12/12 for flower) is essential.

Climate Management: Advanced HVAC systems are needed to maintain specific temperature ranges (often slightly different for day/night and veg/flower) and relative humidity levels (typically decreasing during the flower stage to enhance resin production and prevent mold). Consistency is key.

Air Management: Robust air circulation via fans prevents stagnant air, helps manage microclimates within the canopy, and strengthens plant structures. Filtered air exchange systems remove contaminants and replenish CO2, potentially supplemented during peak growth phases to boost photosynthetic rates.

Specific Nutrient Strategy: Plants require a precise diet of macronutrients (NPK) and micronutrients. This involves:

Using high-grade, often cannabis-specific, nutrient formulations.

Implementing detailed feeding schedules that adapt to the plant’s changing needs during vegetative growth versus flowering.

Constantly monitoring and adjusting the pH and EC (Electrical Conductivity) or PPM (Parts Per Million) of the nutrient solution or runoff to ensure optimal nutrient uptake.

Purified Water Supply: Starting with clean water is vital. Reverse Osmosis (RO) filtration is standard practice, removing chlorine, chloramine, and dissolved solids, providing a blank slate for adding precise nutrient formulations. The pH of the water must be carefully adjusted (usually within the 5.5-6.5 rane, varying by medium) before feeding.

Skilled Cultivation Team: Growing temperamental exotic strains often requires more than just following a guide. Experienced cultivators bring invaluable knowledge, keen observation skills to diagnose plant needs or stresses early, and the ability to apply advanced techniques (e.g., specific pruning, training like SCROG or SOG) to maximize quality and yield.

Integrated Pest Management (IPM): A proactive approach to pest and disease control is crucial, emphasizing prevention. This includes maintaining impeccable facility hygiene, regular plant inspection, utilizing beneficial insects, and using organic or naturally derived controls only as a last resort, they don’t impact the final product’s purity or flavor.

Purpose-Built Facility: A clean, secure, and well-designed cultivation facility is essential. This means separate, controlled zones for propagation, vegetation, flowering, drying, curing, and trimming to prevent cross-contamination and optimize environmental conditions for each stage. Strict sanitation protocols are enforced.

Understanding the Entire Exotic THCA Flower Process

With the necessary elements in place, the actual process of cultivating Exotic THCA flower unfolds through a series of carefully managed stages. Each phase logically follows the previous one, contributing distinct characteristics that define the final product’s quality. Also, patience and precision are the guiding principles. Any misstep along the way can compromise the unique potential held within those prized exotic genetics. It’s a meticulous progression to the expertly finished flower. Here’s a breakdown of the key steps involved:

Strain Selection & Sourcing: Reiterating its importance, this initial step involves choosing specific exotic cultivars renowned for their unique terpene expression, high THCA potential, visual appeal (bag appeal), and desired effects profile. Genetics are sourced as seeds or clones from trusted, verifid providers.

Germination/Cloning: Seeds are carefully sprouted into seedlings using reliable methods, or cuttings (clones) are taken from healthy, established mother plants and induced to root in suitable plugs or cubes. This stage establishes the young plant life that will form the basis of the crop.

Vegetative Stage: Once rooted, the young plants enter the vegetative phase, characterized by rapid growth of leaves, stems, and branches. Under a long light cycle (typically 18+ hours daily), the focus is on building a strong plant structure and robust root system capable of supporting later THCA flower development. Nitrogen-rich nutrient formulas fuel this growth. Training techniques like topping or LST might be used to shape the plant for optimal light exposure and yield. This stage typically lasts several weeks.

Flowering Stage: The transition to flowering is triggered by changing the light cycle to 12 hours of light and 12 hours of uninterrupted darkness. The plant redirects its energy towards producing flowers (buds). Nutrient formulas are adjusted to lower nitrogen and increase phosphorus and potassium (PK), supporting bud formation, density, and resin gland (trichome) production. Environmental factors like humidity are carefully controlled, often lowered to optimize trichome development and reduce mold risk. The duration varies significantly based on the strain, often lasting 8-12 weeks or more for some exotic varieties. Close monitoring of trichome maturity is vital.

Flushing (Optional but Common): During the last 1-2 weeks before the anticipated harvest, many cultivators cease feeding nutrients and provide only pH-adjusted water. This practice, known as flushing, aims to encourage the plant to use up remaining nutrients, potentially resulting in a smoother taste and cleaner burn in the final product. Its efficacy is debated, but it remains prevalent, particularly in soilless cultivation.

Harvesting: Determining the precise harvest window is critical for capturing peak quality. Growers use magnification to inspect the trichomes on the buds, typically harvesting when they transition from clear to mostly cloudy/milky, with a small percentage turning amber. This indicates peak THCA levels and terpene maturity. The harvesting process involves carefully cutting down plants or branches, handling them gently to preserve trichomes.

Trimming: Soon after harvest (wet trimming) or after a preliminary drying period (dry trimming), the excess fan leaves and smaller sugar leaves surrounding the buds are removed. For Exotic THCA flower, meticulous hand-trimming is strongly preferred over machine trimming. Although labor-intensive, hand-trimming preserves the delicate trichomes and the natural shape of the buds far more effectively, leading to a visually superior and potentially more potent product.

Drying: This slow, controlled process is essential for preservation and quality. Trimmed buds or branches are typically hung in a dark environment with stable temperature (around 60-70°F or 15-21°C) and humidity (around 55-65% RH), along with gentle, indirect airflow. The goal is to reduce the water content gradually over 7-16 days. Drying too quickly volatilizes terpenes (damaging aroma/flavor) and degrades cannabinoids. Buds are typically ready for curing when the smaller stems snap rather than bend.

Curing: Considered a vital step for achieving premium quality, curing involves placing the dried buds into airtight containers (commonly glass jars) for several weeks to months. Stored in a cool, dark place, these containers are periodically opened (“burped”) to release moisture buildup and allow for fresh air exchange. This process slows down the degradation of cannabinoids and terpenes, breaks down chlorophyll (reducing harshness), enhances flavor and aroma complexity, and ensures a smooth experience. Proper curing is often what separates truly exceptional exotic THCA flower from merely good flower.

Quality Control & Testing: Before reaching the market, representative samples undergo rigorous quality checks. This includes independent, third-party laboratory testing to verify THCA potency (and ensure Delta-9 THC compliance), screen for contaminants like pesticides, heavy metals, molds, and bacteria, and often analyze the terpene profile. Visual inspection for consistency, trim quality, structure, and overall appeal is also performed.

Packaging: The final step involves carefully packaging the graded, tested, and cured flower into appropriate containers designed to protect its quality, comply with regulations (child-resistance, labeling), and showcase its premium nature. This leads directly into preparing the product for sale.

Recommended products

Why is Each Step Vital to the Exotic THCA Flower Making Process Anyways?

Comprehending the sequence of cultivating Exotic THCA flower is one thing but appreciating the fundamental necessity of each specific step illuminates why producing this level of quality is such an involved endeavor. Neglecting or poorly executing any phase introduces a vulnerability, potentially undermining all the effort invested elsewhere and preventing the flower from achieving its full, unique genetic expression. So, let’s examine the critical contribution of each phase:

Strain Selection & Sourcing: This dictates the ultimate potential. You can’t conjure exotic traits—unique aromas, vibrant colors, specific bud structures—from genetics that don’t inherently possess them. Starting with subpar or unstable genetics ensures a disappointing outcome, no matter how skilled the grower. It’s the genetic blueprint that defines the possibilities.

Germination/Cloning: A robust start yields healthy, vigorous plants better equipped to thrive throughout the growth cycle. Weak seedlings or poorly rooted clones are more susceptible to stress, pests, and diseases, leading to reduced yields and potentially compromised quality. This step builds the essential foundation for future growth.

Vegetative Stage: This phase constructs the plant’s “infrastructure.” Developing a strong root network and a well-structured canopy through optimal nutrition, light, and training is crucial for supporting abundant flower production later. A plant that struggled during its vegetative phase lacks the framework to produce dense, high-quality exotic buds.

Flowering Stage: This is when the desired product—the flower—develops. Precise management of the light cycle, climate (temperature, humidity), and nutrient delivery directly impacts bud density, size, trichome development (THCA production), and terpene synthesis. Environmental stress or nutrient imbalances during flowering can severely diminish potency, flavor, aroma, and yield.

Flushing (if practiced): Advocates believe this step is key to refining the final experience, aiming to purge residual nutrient salts that might negatively affect the taste or smoothness when consumed. While its impact is debated, careful flushing is intended as a final purification step.

Harvesting: Timing the harvest correctly is paramount. Harvest too soon, and the trichomes won’t be fully mature, resulting in lower potency and less developed terpene profiles. Harvest too late, and THCA may begin to degrade, potentially altering the effects and diminishing the vibrancy of the flower. Identifying that peak window captures the strain’s optimal chemical expression.

Trimming: Careful hand-trimming is vital for both the aesthetics and quality of exotic THCA flower. It protects the fragile trichome heads, where the majority of cannabinoids and terpenes reside, which can be easily knocked off by machines. A meticulous trim also enhances the visual appeal (“bag appeal”) and ensures a smoother experience by removing potentially harsh leaf matter. It shows respect for the finished bud.

Drying: Slow and controlled drying cannot be rushed. Rapid drying using heat evaporates volatile terpenes, essentially destroying the flower’s unique aroma and flavor profile. It can also lock in chlorophyll, leading to a harsh, unpleasant taste. Proper drying preserves the delicate compounds synthesized during flowering and prevents mold growth during the subsequent curing phase.

Curing: This crucial refinement stage significantly differentiates top-tier exotic flower. Curing allows moisture levels within the buds to stabilize, facilitates the breakdown of undesirable compounds like chlorophyll and sugars, and enables terpenes to mature and meld, creating a more complex and nuanced aroma and flavor. A proper cure leads to enhanced smoothness, better burn quality, and improved shelf stability. Neglecting the cure results in a harsh, less flavorful product.

Quality Control & Testing: This step ensures product safety, transparency, and verifies quality claims. Independent lab testing confirms the THCA potency, ensures compliance with legal Delta-9 THC limits, and crucially, screens for potentially harmful contaminants. Terpene analysis provides valuable information about the flower’s profile. This builds consumer trust and validates the quality achieved.

Packaging: Appropriate packaging is the final safeguard for the meticulously cultivated flower. It must protect the buds from physical damage and, more importantly, shield them from environmental factors like light, oxygen, and moisture fluctuations, all of which rapidly degrade the quality, potency, and aroma that define exotic flower.

In essence, achieving genuine Exotic THCA flower quality demands excellence without compromise at every single point in the process. Each step builds upon the last, contributing uniquely to the final symphony of characteristics that make the flower truly special.

How is the Packaging Itself for Exotic THCA Flower Made and Designed?

The careful journey of creating Exotic THCA flower culminates in its packaging, a step far more significant than simply putting buds in a container. The packaging serves as the final guardian of quality, meticulously designed to protect the flower’s integrity, preserve its unique characteristics, and ensure it reaches the consumer in optimal condition. It must shield the delicate trichomes from physical damage, maintain the ideal moisture level achieved during curing, block degrading UV light, prevent aroma loss and oxidation from air exposure, meet all regulatory requirements (such as child-resistant features and labeling), and effectively communicate the premium nature and branding of the exotic product within. The choice of materials and structural design are therefore critical engineering and marketing decisions.

Biodegradable Jars

These environmentally conscious containers are typically crafted from plant-derived bioplastics or composite materials. Polylactic acid (PLA), synthesized from renewable resources like corn starch or sugarcane, is a frequent choice, alongside materials incorporating bamboo fibers, wood pulp, or other sustainable elements. Manufacturing generally employs injection molding or compression molding techniques, where the bioplastic resins or composite mixtures are heated and shaped within precise molds to form the jar body and corresponding lid. A key design focus is achieving an effective seal to preserve freshness, often incorporating specialized liners or closure designs. While pigments can be added for branding, the aesthetic often emphasizes natural tones, aligning with the sustainable sourcing. Although not inherently UV-proof, the opacity common to many of these materials provides a degree of light protection.

The core design philosophy balances preservation needs with ecological responsibility. These jars are engineered with sufficient rigidity to prevent the enclosed buds from being crushed during handling and transport. The effectiveness of the seal is paramount; designers concentrate on lid mechanisms (usually screw-top) and potential inner seals (like pressure-sensitive or foam liners) to minimize air exchange and moisture vapor transmission, thereby protecting the flower’s cured state, terpene profile, and THCA content. The surface area allows for effective labeling or direct printing, enabling brands to convey necessary product information and highlight their commitment to sustainability. The material selected must also be non-reactive, ensuring it doesn’t alter the flower’s taste or aroma.

Pros:

Reduced environmental impact compared to traditional petroleum plastics.

Often opaque, offering inherent protection from light degradation.

Solid structure protects buds from physical compression.

Appeals to environmentally aware consumers and brands.

Can be designed to provide good airtight seals.

Cons:

Typically, it is at higher cost than conventional plastic containers.

Seal quality and consistency can vary based on design and manufacturing precision.

May not offer the same level of long-term inertness or UV protection as specialized glass.

Effective biodegradation often requires specific industrial composting facilities.

Glass Jars

A timeless option for premium THCA flower products, glass jars are produced by melting a mixture of silica sand, soda ash, and limestone at very high temperatures (over 2700°F or 1500°C) in a large furnace. The resulting molten glass is then precisely shaped into jars using methods such as blow molding (using compressed air to inflate a ‘gob’ of molten glass within a mold) or press molding. Lids, manufactured separately usually from metal or plastic, are critical components designed with liners (e.g., plastisol, foam, or pulp/poly liners) engineered to create an airtight seal when properly closed via screw threads or mechanical clamps (like those on bail-top jars). Design choices involve selecting glass clarity (clear for maximum visibility vs. amber, green, or cobalt blue for UV filtering) and determining the appropriate glass thickness for durability and premium feel.

Glass is highly valued for its chemical inertness; it does not react with the cannabis constituents, ensuring the original terpene and cannabinoid profile remains untainted. The design emphasizes achieving a hermetic seal – precision threads on screw tops and robust gasket systems on bail tops are vital for preventing oxygen ingress and maintaining the flower’s internal humidity. While clear glass beautifully showcases the visual attributes of exotic THCA flower, UV-protective colored glass (especially amber) is superior for long-term storage as it filters out damaging light wavelengths. The smooth, non-porous surface provides an excellent substrate for high-quality labels, printing, or etching, enhancing the product’s perceived value and shelf presence. Its rigidity offers complete protection against physical crushing.

Pros:

Chemically inert, offering superior preservation of flavor and aroma.

Capable of providing an excellent, long-lasting airtight seal.

Provides a high-end, premium aesthetic and tactile experience.

Glass is infinitely recyclable (though lids may not be).

Allows clear product visibility (using clear glass).

Offers effective UV protection options (colored/coated glass).

Completely rigid structure prevents bud compression.

Cons:

Fragile and susceptible to breakage.

Heavier and bulkier than other packaging formats.

Clear glass provides zero UV protection.

Generally, it is more expensive than flexible packaging or plastic jars.

Reliability of the seal depends heavily on the lid and liner quality.

Recommended products

Mylar Bags

Often referred to generically as Mylar, these flexible pouches are typically sophisticated multi-layer laminates. A common construction includes an outer layer of biaxially-oriented polyethylene terephthalate (BoPET, the actual Mylar® is a brand name) for strength, stiffness, and a printable surface; a crucial middle layer of aluminum foil acting as a highly effective barrier against light, oxygen, and moisture; and an inner layer of a sealant film like food-grade polyethylene (PE) which enables heat-sealing. These layers are bonded together using adhesives in a lamination process. The laminated material is then cut and formed into bags, often incorporating features such as resealable zipper closures, tear notches for convenient opening, expandable bottom gussets allowing the bag to stand upright, and sometimes hang holes for retail display. High-resolution printing is applied to the outer layer, providing ample space for branding and required information.

The design of these bags leverages the properties of the multi-layer construction to maximize preservation and convenience. The embedded aluminum foil layer is key, rendering the bag opaque (blocking 100% of light) and creating a formidable barrier against oxygen and water vapor transfer, which helps maintain the THCA flower‘s freshness, potency, and aromatic profile. While the flexible nature means less protection against crushing compared to rigid containers, it allows for efficient storage and transport. Zipper closures offer resealability, enhancing user convenience, while the initial heat seal provides tamper evidence. Child-resistant zipper mechanisms are frequently required by regulation and are integrated into the design. The large printable surface area is ideal for vibrant graphics and detailed compliance text.

Pros:

Outstanding barrier properties (light, oxygen, moisture).

Lightweight, flexible, and space-efficient for storage and shipping.

Complete opacity ensures full UV protection.

Often feature convenient resealable zippers and tear notches.

Extensive surface area for branding and regulatory information.

Can be readily designed with certified child-resistant closures.

Cost-effective, especially compared to glass.

Cons:

Provides minimal protection against physical crushing of the flower.

Effectiveness of zipper seals may diminish over repeated use.

Can have a less premium perception than rigid containers like glass.

Multi-material laminate structure makes recycling challenging or impossible.

Vacuum Sealed Bags

Bags intended for vacuum sealing are constructed from robust, multi-layer plastic films specifically chosen for high tensile strength, puncture resistance, and low oxygen permeability. Common material combinations include polyethylene (PE) for sealing properties and nylon (polyamide, PA) for barrier performance and strength. Often, one surface of the bag interior features an embossed or textured pattern; these channels allow air to be effectively withdrawn by a vacuum sealer machine before the final heat seal is made. The films are produced via co-extrusion, where multiple layers of molten plastic are extruded together, then formed into bags (usually sealed on three sides) or supplied as rolls for custom sizing.

The fundamental design principle behind vacuum sealing is the near-complete removal of atmospheric oxygen from the package. By evacuating the air before sealing, the process dramatically inhibits oxidative degradation of cannabinoids and terpenes, significantly extending the shelf life and preserving the initial freshness, aroma, and potency of the flower. This method is particularly well-suited for long-term storage or for preserving bulk quantities before final retail packaging. The resulting package is very compact and effectively contains odors. While the tight seal offers some form-fitting support, vacuum sealing provides little inherent protection against external crushing forces and can even compress delicate buds if excessive vacuum is applied.

Pros:

Suprior preservation by minimizing oxygen exposure, greatly slowing degradation.

Maximizes shelf life, ideal for long-term storage scenarios.

Effectively seals in aromas until the package is opened.

Results in a highly compact, space-saving package.

The bag material itself is relatively low-cost.

Cons:

Requires access to a compatible vacuum sealer machine.

Offers minimal protection from crushing; can potentially compress buds.

Typically, not resealable once opened (must be cut).

Generally, it lacks the shelf appeal for direct retail presentation.

Contributes to plastic waste; recycling depends on local capabilities for multi-layer films.

Plastic Vials/Tubes

These rigid containers are most commonly produced via injection molding. In this high-volume manufacturing process, molten plastic resin – frequently polypropylene (PP) due to its good chemical resistance, stiffness, and heat tolerance, or sometimes polystyrene (PS) or polyethylene terephthalate (PET) – is forced under high pressure into a precisely crafted metal mold. After the plastic cools and solidifies within the mold cavity, the mold opens to eject the finished vial or tube. Lids are manufactured separately, often using the same process, and are frequently designed with push-and-turn or snap-cap mechanisms to meet child-resistance standards. Tamper-evident features, like shrink bands applied over the lid or integrated breakable rings, can also be incorporated. Design options include clear plastic for visibility or opaque plastic for light protection.

Plastic vials and tubes are typically designed to hold smaller quantities of exotic THCA flower, such as single grams, or are commonly used for pre-rolled products. Their inherent rigidity provides excellent protection against crushing during handling and transport. Polypropylene is often preferred as it is relatively inert and less likely to interact with the flower’s sensitive compounds compared to some other plastics. Child-resistant closures are a key design focus to comply with regulations in many markets. While they provide a reasonable seal, the long-term airtightness might not equal that of high-quality glass jars or foil-lined bags, depending heavily on the precision of the lid fit and seal design. They offer a practical, often cost-effective packaging solution, particularly for smaller product units or samples.

Pros:

Provides good protection against physical crushing due to rigid walls.

Frequently incorporates required child-resistant and tamper-evident features.

Relatively inexpensive manufacturing cost.

Lighter weight than comparable glass containers.

Available in clear (for viewing) or opaque (for light protection) versions.

Well-suited for packaging single grams, small quantities, or pre-rolls.

Cons:

Seal quality and long-term airtightness can be variable.

May be perceived as less premium than glass packaging.

Environmental concerns associated with plastic production and disposal (though PP is recyclable).

Potential for very long-term, low-level interaction between plastic and terpenes (less likely with PP than some other plastics).

Restricted to how much you can have in them.

Recommended products

For Retailers and Consumers: Ways to Identify Properly Made Exotic THCA Flower

Navigating the expanding marketplace for THCA flower requires a discerning eye, especially when seeking out products labeled as “Exotic”. Both retailers aiming to curate a high-quality inventory and consumers searching for a truly special experience need reliable methods to distinguish genuinely well-crafted exotic flower from products that might use the label without delivering the substance. Identifying properly made Exotic THCA flower involves looking beyond the name and assessing a combination of verifiable data, sensory cues, and physical characteristics that reflect superior genetics and meticulous cultivation, harvesting, and curing practices. It’s about recognizing the tangible signs of quality that set true exotic flower apart.

How Retailers Can Identify Properly Made Exotic THCA Flower

For retailers, accurately identifying and sourcing authentic Exotic THCA flower is crucial for maintaining credibility and meeting the expectations of discerning customers. This involves a diligent vetting process that goes beyond surface appearances, specifically:

Vetting Sources Thoroughly: Build strong relationships with cultivators and distributors who have a proven track record for producing high-quality, genetically unique cannabis and who operate with transparency. Inquire about their specific cultivation techniques, genetics portfolio (especially for exotic strains), drying and curing protocols, and quality control measures. Prioritize partners who are open, knowledgeable, and demonstrably committed to quality.

Insisting on Comprehensive & Verifiable Lab Reports (COAs): Never stock a product without a corresponding Certificate of Analysis (COA) for that specific batch. Critically review the COA, ensuring it’s recent and from a reputable, accredited lab (ISO 17025 certification is the standard). Key items to check:

Potency: Confirm high THCA levels appropriate for an exotic strain and verify Delta-9 THC compliance (<0.3%).

Safety Screening: Ensure passing results for pesticides, heavy metals, residual solvents (if applicable), mycotoxins, and microbial contaminants. Any failure is unacceptable.

Terpene Analysis: Examine the terpene profile. Does it align with the expected characteristics of the specific exotic strain? Higher total terpene content often indicates a more aromatic and flavorful product.

Conducting In-Depth Sensory Evaluations: Rely on experienced staff to physically inspect samples:

Visual Inspection (Bag Appeal): Look for striking visual characteristics often associated with exotic strains – unique coloration, dense trichome coverage giving a “frosty” or crystalline appearance, well-formed and often dense bud structure, and evidence of careful hand-trimming. Red flags include excessive leafiness, loose structure, dull coloration, or visible mold/pests.

Aroma Assessment (Nose): The aroma should be potent, distinct, and complex upon opening the container, reflecting the strain’s unique terpene profile (e.g., intense fruit, fuel/gas, candy, or unusual floral/spicy notes). Weak, grassy, hay-like, musty, or chemical smells indicate poor handling or curing.

Tactile Assessment: Gently handle the buds. They should feel sticky to the touch (indicating high resin content), dense, and slightly springy. Avoid THCA flower that is excessively dry and brittle or overly moist and spongy.

Evaluating Batch Consistency: Assess the uniformity of quality within a single batch and, over time, the consistency delivered by the supplier across multiple batches. True quality producers maintain high standards consistently.

Examining the Final Packaging: Ensure the THCA flower is presented in professional, compliant (child-resistant, properly labeled), and adequately sealed packaging that protects it from degradation. Subpar packaging can reflect poorly on the overall quality commitment.

How Consumers Can Identify Properly Made Exotic THCA Flower

Consumers looking for genuine Exotic THCA flower can also employ the following several strategies to increase their chances of finding a high-quality product that lives up to the description:

Patronize Reputable Retailers: Shop at licensed dispensaries or retailers known for their knowledgeable staff, curated selection, and commitment to quality. Such retailers are more likely to source from reliable producers.

Investigate Brand Reputation: Before purchasing, do some research on the brand producing the flower. Look for brands specializing in premium or exotic strains. Check their website for information on their growing practices or genetics. Online reviews can offer clues, but maintain a healthy skepticim.

Request Access to Lab Reports (COAs): Ask the budtender if you can view the COA for the product. Many brands now include QR codes on their packaging that link directly to the lab results online. Familiarize yourself with reading a COA – check for potency (high THCA, compliant Delta-9), passing safety tests, and the terpene profile.

Utilize Sensory Clues (When Possible):

Sight: If you can see the THCA flower before buying (through packaging windows or in display jars), look for visual indicators of quality: a thick coating of visible trichomes (frostiness), vibrant or unique colors, dense bud structure, and a clean trim. Be wary of flower that looks brown, overly leafy, or poorly formed.

Smell: While pre-packaged goods limit pre-purchase smelling, upon opening your purchase, the aroma should be immediate, strong, pleasant, and characteristic of the described strain profile. A lack of distinct aroma or any unpleasant off-smells (hay, mildew) suggests lower quality or improper handling.

Feel (After Purchase): Once home, assess the tactile qualities. The buds should feel somewhat sticky, dense, and appropriately cured (not overly dry or wet).

Understand Price Expectations: Producing genuine exotic THCA flower requires significant resources, expertise, and often lower yields due to specific plant needs. Consequently, expect authentic exotic strains to be priced higher than standard flower. Be cautious of products labeled “exotic” but sold at rock-bottom prices, as this may indicate compromises in quality or authenticity.

Assess the Packaging: Look for professional, well-sealed packaging that protects the flower and includes all legally required information (strain name, potency, warnings, batch ID, manufacturer details, potentially a COA QR code). Tamper-evident seals add a layer of confidence.

Evaluate the Experience: The ultimate test is consumption. High-quality exotic THCA flower should provide a smooth, flavorful experience with effects (like feelings of relaxation, euphoria, or focus) consistent with its described profile and potency. Harshness, poor flavor, or weak effects suggest lower quality.

Crafting Premium Exotic THCA Flower Really is an Intricate Process!

The path from a carefully selected exotic seed to the final packaged flower is far more than mere agriculture; it’s an intricate tapestry woven with threads of advanced horticultural science, technological precision, patient observation, and undeniable artistry. Achieving the unique characteristics that define “exotic”—the captivating aromas, striking visuals, and pronounced effects—demands an unwavering dedication to optimizing every single phase. It requires cultivators who possess not only deep botanical knowledge but also an intuitive understanding of the plant’s needs, guiding it meticulously through its lifecycle. The resulting Exotic THCA flower, radiating quality from its trichome-laden surface to its complex terpene profile, stands as a proud testament to this intensive craft, offering an experience that elevates appreciation for the remarkable potential held within the cannabis plant.

To Buy Exotic THCA Flower Click Here

Recommended products

-

Blazed Exotic THCA Flower

$36.99$79.99 -

THCA Moonrocks – Gold Line

$57.99$89.99 -

Exotic THCA Pre-Rolls Gold Line – 3-Pack/6 Pack

$36.99$69.99