Imagine a perfectly cultivated cannabis flower, already a gem of nature’s artistry, taken to a whole new level of intensity. Picture that exquisite bud enveloped in a sparkling white coat, resembling a freshly fallen snowball glistening in the sun. This captivating creation is the Exotic THCA snowballs, a product designed for those seeking a remarkably potent experience, combining premium flower with the purified essence of its primary cannabinoid.

But how does this intriguing transformation happen? What alchemy turns beautiful bud into a potent, powder-dusted marvel? The journey involves not just expert cultivation but also precise laboratory science, culminating in a truly unique cannabis product.

TO BUY THCA SNOWBALLS CLICK HERE

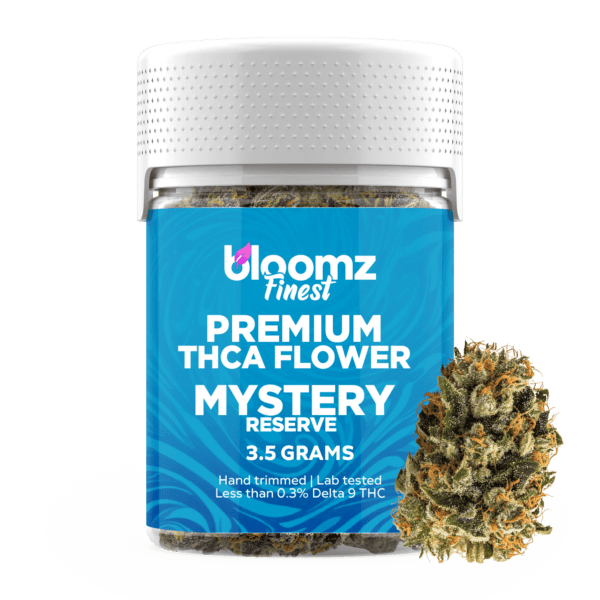

Recommended products

A Quick Insight into What THC and THCA Snowballs are

With Exotic THCA Snowballs, initially you notice the word: “Exotic”– a term signifies cannabis strains possessing rare or unique genetics, often resulting from specialized breeding programs or originating from specific landraces. Exotic strains stand out due to their distinctive terpene profiles, striking visual characteristics, and overall novelty compared to more common cultivars. This base flower, often cultivated indoors to maximize its boutique potential, already represents a premium category sought after for its unique character.

Next, we introduce the “THCA Snowball” aspect. As previously discussed, Snowballs involve coating cannabis flower with a layer of highly purified THCA isolate – the crystalline, non-psychoactive precursor to THC, often exceeding 95% purity. When heated, this THCA converts to Delta-9 THC, delivering potent effects. By adding this frosty coating to the already desirable exotic flower, the overall THCA concentration of the product skyrockets far beyond what even potent exotic strains can achieve naturally. This enhancement process targets users seeking significantly amplified potency levels.

Therefore, Exotic THCA Snowballs represents the pinnacle of this enhancement process. It starts not just with any flower, but specifically with a carefully selected exotic strain chosen for its unique aroma, flavor, and appearance. This premium core is then meticulously coated with high-purity THCA isolate. The objective is to craft a product that offers the best of both worlds: the unique and captivating sensory experience delivered by the exotic flower’s terpenes and genetics, combined with the exceptionally potent effects enabled by the concentrated THCA isolate layer. It’s a synergistic creation aimed at the connoisseur market.

This fusion constructs Exotic THCA Snowballs as a truly specialized product within the cannabis and hemp space (often produced using high-THCA hemp flower to maintain legal compliance under the <0.3% Delta-9 THC threshold pre-combustion). They appeal to users who appreciate the nuances of rare genetics and terpene profiles but also desire an intensely powerful experience that standard flower cannot provide. It’s about elevating both the sensory journey and the potency potential simultaneously, resulting in a product that looks, smells, tastes (reflecting the base flower), and feels distinct from anything else on the marketplace.

What is Initially Needed to Make Exotic THCA Snowballs?

Creating genuine Exotic THCA Snowballs requires a synergy between top-tier cultivation and advanced extraction/purification capabilities. It’s a multi-faceted process demanding high-quality inputs and specialized expertise for each distinct component before they are carefully combined. Think of it as preparing two exceptional ingredients separately before skillfully bringing them together for the final presentation. Failure in either the cultivation or the isolation phase will compromise the end result.

For Component 1: The Premium Exotic THCA Flower Base:

Elite & Suitable Genetics: The foundation must be exceptional. This involves selecting strains known for producing high-quality indoor flower with desirable traits:

Potent THCA Profile: Starting with flower already rich in THCA.

Robust Terpene Profile: To provide the underlying aroma and flavor, as the isolate itself is largely odorless.

Dense Bud Structure: Buds need sufficient density and surface area complexity to hold the isolate coating effectively without crumbling. Wispy or loose flower is unsuitable.

Visual Appeal: Underlying color and structure contribute to the final aesthetic.

High-Standard Indoor Cultivation Facility: All the prerequisites for growing premium indoor flower apply:

Immaculate, light-proof, environmentally controlled grow rooms.

Advanced horticultural lighting (LEDs preferred).

Precision HVAC-D systems for managing temperature, humidity, and VPD.

Sophisticated air filtration and circulation.

Optimized growing medium (hydroponics, soilless mixes, or indoor living soil)

Purified water source (RO water).

Skilled Cultivation Team: Experienced growers capable of consistently producing dense, potent, terpene-rich, and perfectly cured THCA flower that meets the structural requirements for becoming a Snowball base.

Recommended products

For Component 2: The High-Purity THCA Isolate Coating:

Quality Cannabis Biomass: Input material for extraction, typically consisting of cannabis trim, shake, or even whole flower (often lower grade than the THCA Snowball base flower, selected primarily for THCA content). The quality and cannabinoid profile of the starting biomass influence the efficiency and final purity of the isolate.

Professional Extraction Equipment: Commercial-grade systems designed for safely and efficiently stripping cannabinoids and terpenes from the plant material. Common methods include:

Hydrocarbon Extraction: Using solvents like butane (BHO) or propane, known for efficiency in capturing cannabinoids and terpenes but requiring stringent safety protocols and equipment (closed-loop systems).

Ethanol Extraction: Using cold or warm ethanol. Effective for large volumes but requires careful post-processing to remove residual solvent.

Supercritical CO2 Extraction: Uses carbon dioxide under high pressure and temperature. Known for safety and selectivity but involves high equipment costs.

Advanced Refinement & Isolation Technology: Equipment and processes to purify the crude cannabis extract and isolate the THCA compound:

Crystallization/Recrystallization Reactors: Precisely controlling temperature and solvent ratios (using solvents like pentane, heptane, or others) to encourage THCA molecules to crystallize out of the solution, leaving impurities behind. Multiple rounds may be needed. Requires vacuum filtration (Buchner funnels) and drying ovens (vacuum ovens preferred to purge residual solvents gently).Chromatography: Techniques like flash chromatography or preparative High-Performance Liquid Chromatography (Prep HPLC) can separate compounds based on their chemical properties, allowing for highly precise isolation of THCA. Requires significant investment and expertise.

Post-Extraction Filtration/Winterization: Removing fats, waxes (lipids), and chlorophyll from the crude extract, typically using cold ethanol and filtration.

Solvent Recovery Systems: Rotary evaporators or falling film evaporators to remove extraction solvents.

Decarboxylation Equipment (Optional, for other uses): Reactors for converting THCA to THC if needed for other product lines, but not for making THCA isolate.

Isolation Equipment: This is key. Techniques vary but often involve:

Skilled Extraction & Chemistry Team: Personnel with deep knowledge of chemistry, extraction techniques, purification methods, solvent handling safety, and equipment operation are essential for producing safe, high-purity isolate consistently.

Laboratory Testing Capabilities (Internal or Third-Party): Crucial for verifying the purity of the THCA isolate (aiming for 99%+) and ensuring residual solvents are well below mandated safety limits. Testing also verifies the potency of the base flower.

For the Coating Process:

Defined Application Method & Standard Operating Procedure (SOP): A consistent, documented technique is needed to apply the isolate powder evenly onto the flower surface without causing damage or excessive shedding. This SOP outlines the specific steps, materials, and quality checks.

Controlled & Clean Application Environment: The coating process must occur in a clean, dedicated space with controlled temperature and humidity to prevent contamination of the final product and ensure the isolate adheres properly without clumping due to moisture. Proper ventilation is also needed if any volatile terpenes are used as binders.

Potential Binding Agent (Optional): While sometimes isolate is applied directly, a minimal amount of a binding agent might be used to improve adherence. This must be carefully selected – typically a light mist of cannabis-derived terpenes or a tiny amount of pure distillate – applied very sparingly so as not to make the flower sticky or alter its primary characteristics significantly. The choice and amount of binder are critical details.

Understanding the Entire Exotic THCA Snowballs Process

Creating Exotic THCA Snowballs is a sophisticated endeavor that marries expert plant cultivation with precise laboratory science and careful artisanal application. It’s a multi-stage relay race where quality must be maintained at each handoff – from growing exceptional flower, to extracting and purifying potent isolate, to delicately combining the two into the final, visually striking product. Here’s a step-by-step breakdown of how these frosty creations typically come to life:

Cultivating the Premium Base Flower: The journey starts with growing exceptional quality indoor cannabis flower, often an “exotic” strain chosen for its structure, terpene profile, and visual appeal. This involves the full meticulous indoor cultivation process:

Starting with elite genetics (seeds or clones).

Nurturing plants through vegetative growth under optimized light, climate, and nutrient conditions.

Inducing and managing the flowering cycle with precision environmental control to maximize bud density, resin production (rich in THCA), and terpene expression.

Harvesting at peak trichome maturity.

Performing a careful hand-trim to preserve bud structure and trichomes.

Executing a slow, controlled dry to preserve volatile compounds.

Patiently curing the flower in airtight containers (often glass) for weeks or months to achieve optimal smoothness, aroma, and flavor. The THCA flower must be perfectly cured before proceeding.

Extracting Crude Cannabis Oil: Concurrently or separately, cannabis biomass (trim, smaller buds, or specifically grown material) is processed to extract cannabinoids. Using methods like BHO, Ethanol, or CO2 extraction, the goal is to efficiently pull the target compounds from the plant material into a concentrated crude oil form.

Refining and Isolating Pure THCA: This is where laboratory precision becomes paramount. The crude extract undergoes several purification steps:

Crystallization: Dissolving the concentrate in a specific non-polar solvent (like pentane or heptane) and manipulating temperature (often cooling) and concentration allows the THCA molecules, which are crystalline in nature, to precipitate out, forming crystals. Impurities tend to remain dissolved in the solvent. The crystals are collected via filtration, washed with cold solvent, and then carefully dried under vacuum to remove all residual solvent traces. This process might be repeated (“recrystallization”) to achieve higher purity.Chromatography: Using advanced techniques like preparative HPLC, the extract is passed through a column packed with specialized material. Different compounds travel through the column at different speeds based on their affinity to the material, allowing for the collection of highly pure fractions of THCA.

Winterization: Dissolving the crude oil in cold ethanol causes undesirable fats, waxes, and lipids to precipitate out, which are then removed via filtration.

Solvent Recovery: The ethanol (or other primary extraction solvent) is removed, typically using rotary evaporators or falling film systems.

Isolation: The refined oil concentrate is then processed to isolate THCA. Common methods include:

The end goal is a fine, white crystalline powder that is 99%+ pure THCA.

Rigorous Quality Control on Both Components: Before combining, both the cured exotic flower and the finalized THCA isolate powder undergo separate, thorough testing by an accredited third-party lab.

Flower Testing: Confirms potency (THCA, Delta-9 THC compliance), terpene profile, and safety (pesticides, microbes, heavy metals).

Isolate Testing: Critically verifies THCA purity (ideally >99%) and screens for residual solvents used during extraction and isolation, ensuring they are below safety action levels.

Preparing the Components for Coating: Selected buds of the premium cured flower, meeting size and structure criteria, are handled carefully. The pure THCA isolate powder is ensured to be of a fine, consistent particle size, free of clumps.

The Coating Process – Applying the “Snow”: This delicate step requires precision and care:

Simple Rolling/Dusting: Gently rolling or tumbling the THCA buds in a container of the isolate powder. Adherence might be less uniform with this method alone.Binder-Assisted Application: Applying a very fine mist of a carefully chosen binding agent (like cannabis-derived terpenes to complement the flower’s profile, or a minuscule amount of high-purity cannabis distillate) to the bud surface immediately before rolling/dusting in the isolate. The binder helps the powder stick more effectively and evenly but must be used extremely sparingly to avoid creating a sticky or wet texture.Electrostatic Coating (Advanced): Some advanced operations might explore electrostatic equipment that charges the isolate particles, causing them to adhere more uniformly to the grounded flower surface, though this is less common.

Method Selection: The most common approach involves gently applying the isolate to the THCA flower. This might be:

Execution: Regardless of method, the application is done carefully in a clean environment to ensure an even, aesthetically pleasing coating that covers the bud surface without significant clumping or damage to the underlying flower structure.

Final Quality Inspection: Once coated, the finished Exotic THCA Snowballs are visually inspected. Checks are made for coating uniformity, adequate coverage, absence of discoloration or contamination, and confirmation that the underlying bud structure remains intact. Any poorly coated or damaged pieces are typically removed.

Careful Packaging: The finished Snowballs are delicate. They must be packaged gently and promptly into containers designed to protect both the flower structure and the easily dislodged isolate coating.

Recommended products

Why is Each Step Vital to the Exotic THCA Snowballs Making Process Anyways?

The creation of a truly exceptional Exotic THCA Snowballs flower hinges on the flawless execution of every single step, from cultivating the base flower to purifying the isolate and applying the final coating. Because it’s a composite product, a weakness in any part of the process compromises the entire result. There’s no hiding subpar flower beneath isolate, nor can poor-quality isolate elevate mediocre bud to premium status. Hence, each phase here plays a critical, synergistic role:

Premium Base Flower Cultivation: This is the soul of the Snowball. The quality of the indoor-grown exotic flower determines the product’s core structure, its underlying aroma and flavor (terpenes), and contributes significantly to the overall experience. Using dense, well-cured, terpene-rich flower ensures the Snowball has substance, character, and structural integrity to hold the coating.

Quality Biomass Selection (for Isolate): While not the final flower, the material used for extraction impacts isolate yield and purity. Starting with cleaner, potent biomass simplifies the purification process and reduces the chances of concentrating undesirable compounds alongside the THCA.

Safe & Efficient Extraction: Proper initial extraction maximizes the yield of cannabinoids from the biomass while minimizing the co-extraction of unwanted compounds like chlorophyll and lipids. Using professional equipment and safe practices is crucial for both quality and personnel safety.

Meticulous Refinement & Isolation: This is critical for potency and safety. Achieving high THCA purity (99%+) maximizes the potency boost provided by the coating. More importantly, rigorous purification and subsequent testing are essential to remove potentially harmful residual solvents used during the process, ensuring the final product is safe for consumption.

Rigorous Quality Control (Components): Testing both the base flower and the isolate before combination is non-negotiable. It verifies the quality and safety of each individual component, ensuring compliance and providing data needed for accurate final product labeling.

Careful Component Preparation: Ensuring the flower is perfectly cured and the isolate is a fine powder, allows for optimal adhesion and a uniform final appearance. Clumpy isolate or overly dry/moist THCA flower will result in a poor coating.

Precise Coating Application: The technique used here directly impacts the product’s aesthetic appeal, the evenness of the added potency, and consumer perception. Sloppy application leads to an unattractive, inconsistent product where the coating may easily fall off. Using minimal, appropriate binders ensures adhesion without negatively affecting quality.

Controlled Drying & Curing (Base Flower): Essential pre-requisites. Attempting to coat improperly dried or cured flower would be disastrous, leading to potential mold issues, poor texture, and terrible flavor. The flower must be perfectly finished first.

Gentle Handling Throughout: Both the base THCA flower and the finished Snowballs are delicate. Careful handling at every stage, especially during trimming, coating, and packaging, is vital to preserve the flower structure and keep the isolate coating intact.

Appropriate Packaging: The final step in preservation. Packaging must protect the fragile Snowball from physical damage and prevent the isolate coating from being rubbed off, while also shielding it from environmental degradation (light, air, moisture).

In short, crafting Exotic THCA Snowballs demands excellence across multiple disciplines – horticulture, chemistry, and careful handling – making each step a critical link in the chain towards the final, potent product.

How is the Packaging Itself for Exotic THCA Snowballs Made and Designed?

Packaging for Exotic THCA Snowballs presents unique challenges and requirements beyond those for standard flower. The primary goal remains preservation – protecting the product from light, air, and moisture degradation – but with Snowballs, there’s the added critical need to safeguard the delicate, powdery THCA isolate coating and the structural integrity of the underlying flower. The packaging must minimize friction and abrasion that could cause the isolate to shed, while also preventing the buds from being crushed or compacted. Design choices often lean towards rigid containers that offer physical protection and potentially showcase the unique visual appeal of the product, while ensuring compliance with safety regulations like child-resistance.

Glass Jars

Manufactured by melting and molding silica sand, soda ash, and limestone, glass jars are a top contender for Snowball packaging. High-quality, often thick-walled glass provides excellent rigidity, crucial for preventing the Snowballs from being crushed or jostled excessively. Clear glass is frequently chosen to highlight the striking visual contrast between the underlying exotic flower (if colors peek through) and the bright white isolate coating. Lids are critical; premium screw-top or bail-top lids with high-quality, inert liners (PTFE, specialized foam) are essential to create a truly airtight seal, preserving both the flower’s cure and preventing moisture from clumping the isolate.

The design inherently minimizes internal movement and surface contact compared to flexible packaging. The smooth glass walls reduce friction, helping to keep the isolate coating intact. Visibility through clear glass allows consumers to inspect the unique appearance before purchase. For longer-term preservation, UV-protective amber or opaque glass can be used, sacrificing visibility for enhanced protection against light degradation. The premium feel of glass aligns well with the high-end positioning of Exotic THCA Snowballs, and the surface allows for elegant branding and detailed labeling.

Pros:

Excellent physical protection due to rigidity, preventing crushing.

Inert material preserves flower’s terpene profile and doesn’t react with isolate.

Smooth surface minimizes friction, helping protect the coating.

Clear glass offers excellent visibility for showcasing the product.

Can provide a superior airtight seal with quality lids/liners.

Premium look and feel aligns with high product value.

Offers UV protection options (colored/opaque glass).

Cons:

Breakable and heavier/bulkier.

Higher packaging cost.

Clear glass offers no UV protection.

Some isolate may still transfer to glass walls with handling/shipping

Biodegradable Jars

These jars, molded from plant-based plastics (like PLA) or composites, offer a sustainable packaging alternative. Their rigid structure provides good physical protection for the THCA Snowballs, similar to glass. Most biodegradable materials are opaque, which inherently shields the product from light degradation. The design focus remains on achieving a secure, airtight seal to maintain freshness and prevent moisture ingress that could affect the isolate coating.

For THC A Snowballs, the rigidity is a key benefit. While opacity prevents visual inspection of the coating pre-purchase, it does offer consistent light protection. The internal surface texture might vary depending on the material, potentially causing slightly more friction than smooth glass. Brands choosing this option often emphasize the combination of a high-tech product (Snowball) with an eco-conscious packaging choice. Effective sealing is crucial to prevent moisture compromising the powdery coating.

Pros:

Good physical protection due to rigid structure.

Environmentally friendlier positioning.

Typically opaque, providing inherent light protection.

Can be designed with effective airtight seals.

Cons:

Prevents visual inspection of the unique Snowball appearance.

Internal surface may cause more friction than glass.

Seal effectiveness and long-term barrier properties can vary.

Higher cost than conventional plastics.

Biodegradation requires specific conditions.

Mylar Bags

Constructed from multi-layer laminates including PET, aluminum foil, and PE, Mylar bags offer excellent barrier properties against light, oxygen, and moisture. They are lightweight and provide ample space for branding. However, their flexibility poses a significant challenge for packaging delicate Snowballs.

The primary design drawback for THCA Snowballs is the lack of rigid protection and the high potential for surface friction. As the bag flexes during handling and transport, the Snowball buds can rub against the inner walls, potentially dislodging a significant amount of the valuable isolate coating. While the barrier properties are excellent for preserving freshness if the seal is good, maintaining the product’s intended form and appearance is difficult. If used, extreme care in handling would be required, perhaps placing buds carefully to minimize movement, but it’s generally considered less suitable than rigid options for this specific product type.

Pros:

Excellent light, oxygen, and moisture barrier properties.

Lightweight and space-efficient.

Large surface area for branding.

Can incorporate CR features.

Cons:

Poor physical protection; flower can be crushed or compressed.

High risk of isolate coating rubbing off due to friction with flexible walls.

Less premium perception compared to jars.

Difficult to recycle.

For Retailers and Consumers: Ways to Identify Properly Made Exotic THCA Snowballs

Identifying high-quality Exotic THCA Snowballs involves assessing more than just the underlying flower or the frosty coating alone; it requires evaluating the synergy between the two and the precision of the process. Given the added complexity and cost involved in making Snowballs, ensuring authenticity and quality is crucial for both retailers managing their premium inventory and consumers seeking a potent, unique experience. Discerning properly made Snowballs means looking for signs of expert cultivation, clean extraction and isolation, skillful application, and appropriate packaging.

How Retailers Can Identify Properly Made Exotic THCA Snowballs

Retailers need to be particularly diligent when sourcing THCA Snowballs, ensuring they are stocking a legitimate, high-quality, and safe product that justifies its premium price point. And so, here’s how they can go about doing just that:

Verify Source Credibility: Partner with reputable brands or producers known for both high-quality indoor/exotic flower and clean, professional extraction/isolation capabilities. Ask about their process for creating Snowballs – where do they source the flower and the isolate? Do they produce both in-house? Transparency is key.

Demand Comprehensive & Transparent Lab Reports (COAs): This is critical. Retailers need COAs for the final combined product. This should ideally include:

Potency: Confirming very high THCA levels and compliant Delta-9 THC. Total cannabinoid potency should also be high.

Safety Testing: Passing results for pesticides, heavy metals, and microbials (testing should ideally be done on the base flower before coating).

Residual Solvents: A specific test confirming residual solvents from the isolate purification process are below legal limits in the final product. This is non-negotiable for safety.

(Optional but helpful: Terpene profile of the base flower).

Conduct Thorough Sensory & Visual Evaluation:

Sight: Look for a generous, relatively uniform coating of fine, white crystalline powder covering well-structured buds. Avoid products that look like loose isolate haphazardly clumped onto flower, or where the coating is patchy or discolored. The underlying flower structure should still be apparent and look appealing. Packaging (ideally jars) should minimize crushed or damaged product.

Smell (Nose): The primary aroma should come from the base flower’s terpenes. Pure THCA isolate is virtually odorless. The product should smell like potent, clean cannabis flower, not chemicals, solvents, or anything artificial.

Feel (Handling): While some shedding is expected, the coating should adhere reasonably well. The underlying flower, if discernible by touch through the coating, should feel properly cured (not wet or overly brittle). Avoid products that feel sticky or excessively powdery/crumbly.

Assess Consistency: Look for consistency in appearance (coating level, bud size/structure) within a single jar or batch. Significant variation might indicate poor process control during coating.

Evaluate Packaging: Ensure the packaging is rigid (preferably glass), well-sealed, compliant (CR features), and protects the delicate THCA product from damage and shedding during transport and display.

How Consumers Can Identify Properly Made Exotic THCA Snowballs

Consumers seeking the intense experience of THCA Snowballs should look for the following indicators to ensure they are getting a well-crafted product:

Choose Reputable Brands & Retailers: Purchase from licensed dispensaries known for quality control and brands recognized for transparency and high standards in both cultivation and extraction.

Look for Detailed Lab Reports (COAs): Ask to see the COA or access it via QR code. Confirm very high THCA potency (often 50%+) and critically, check for passing results on safety tests, especially residual solvents. Be wary if solvent testing is unavailable or fails.

Examine Visual Appearance: The product should look like distinct cannabis buds thoroughly coated in a white, powdery substance (the isolate). It shouldn’t look like loose powder with flower bits mixed in, nor should the coating look sparse, clumpy, or discolored. Ideally, the packaging (like a clear jar) allows for visual inspection.

Trust Your Nose: The dominant scent should be that of the underlying cannabis flower’s terpenes. A lack of cannabis aroma or any chemical or solvent smell is a major red flag.

Consider the Packaging: Look for sturdy, protective packaging, preferably glass jars, that minimizes damage and preserves freshness. Professional presentation often correlates with product quality.

Understand the Price Point: Exotic THCA Snowballs are labor-intensive and require multiple high-value components (premium flower + pure isolate). Expect a significantly higher price compared to regular flower. Unusually low prices might indicate compromises in flower quality, isolate purity, or safety testing.

Start Slow: Due to the significantly enhanced potency provided by the THCA isolate coating, consumers, especially those new to such products, should start with a much smaller amount than they would use for regular flower to assess tolerance.

Crafting Frosty Exotic THCA Snowballs Really is an Intricate Process!

The creation of Exotic THCA Snowballs stands as a fascinating intersection of advanced horticulture and meticulous laboratory science. It’s a process demanding dual mastery – the art of cultivating breathtakingly beautiful and potent exotic flower, coupled with the precision chemistry required to extract and purify THCA to its crystalline essence. Bringing these two elements together into that final, frost-covered bud requires yet another layer of careful technique and handling.

Far from a simple novelty, a well-crafted Snowball represents a complex synergy, a testament to the dedicated pursuit of intensity and unique product forms within the ever-evolving cannabis landscape, offering a powerful experience born from true multi-disciplinary craftsmanship.

TO BUY THCA SNOWBALLS CLICK HERE

Recommended products

-

Exotic THCA Pre-Rolls Gold Line – 3-Pack/6 Pack

$36.99$69.99 -

Exotic THCA Smalls

$179.99$329.99